- Home

- Service

- Plant Wireless Vibration Monitoring System

Comprehensive Solutions for Real-Time Equipment Monitoring

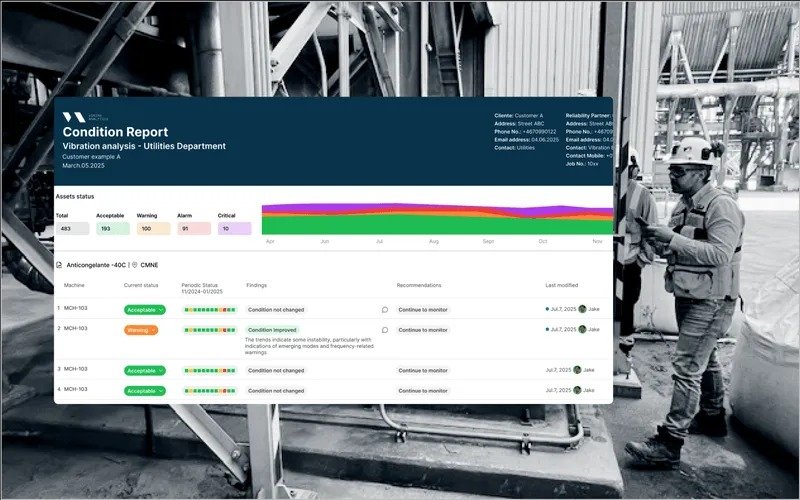

Enhance plant reliability and operational efficiency with advanced wireless vibration monitoring systems. These solutions provide continuous, real-time insights into machinery health, enabling predictive maintenance and minimizing unplanned downtime. Ideal for manufacturing, energy, and process industries, they support proactive decision-making and resource optimization.

Plant Wireless Vibration Monitoring System

Enhancing Operational Reliability

Wireless vibration monitoring systems empower maintenance teams with instant access to critical machine data. By identifying vibration anomalies and potential failures early, they support proactive decision-making and improve equipment uptime. Their integration with IoT platforms enables remote monitoring, making them a vital tool for modern, connected industries.

Plant Wireless Vibration Monitoring System

Enhancing Operational Reliability

Wireless vibration monitoring systems empower maintenance teams with instant access to critical machine data. By identifying vibration anomalies and potential failures early, they support proactive decision-making and improve equipment uptime. Their integration with IoT platforms enables remote monitoring, making them a vital tool for modern, connected industries.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

Smart Wireless Vibration Monitoring

Advanced Tools for Plant Efficiency

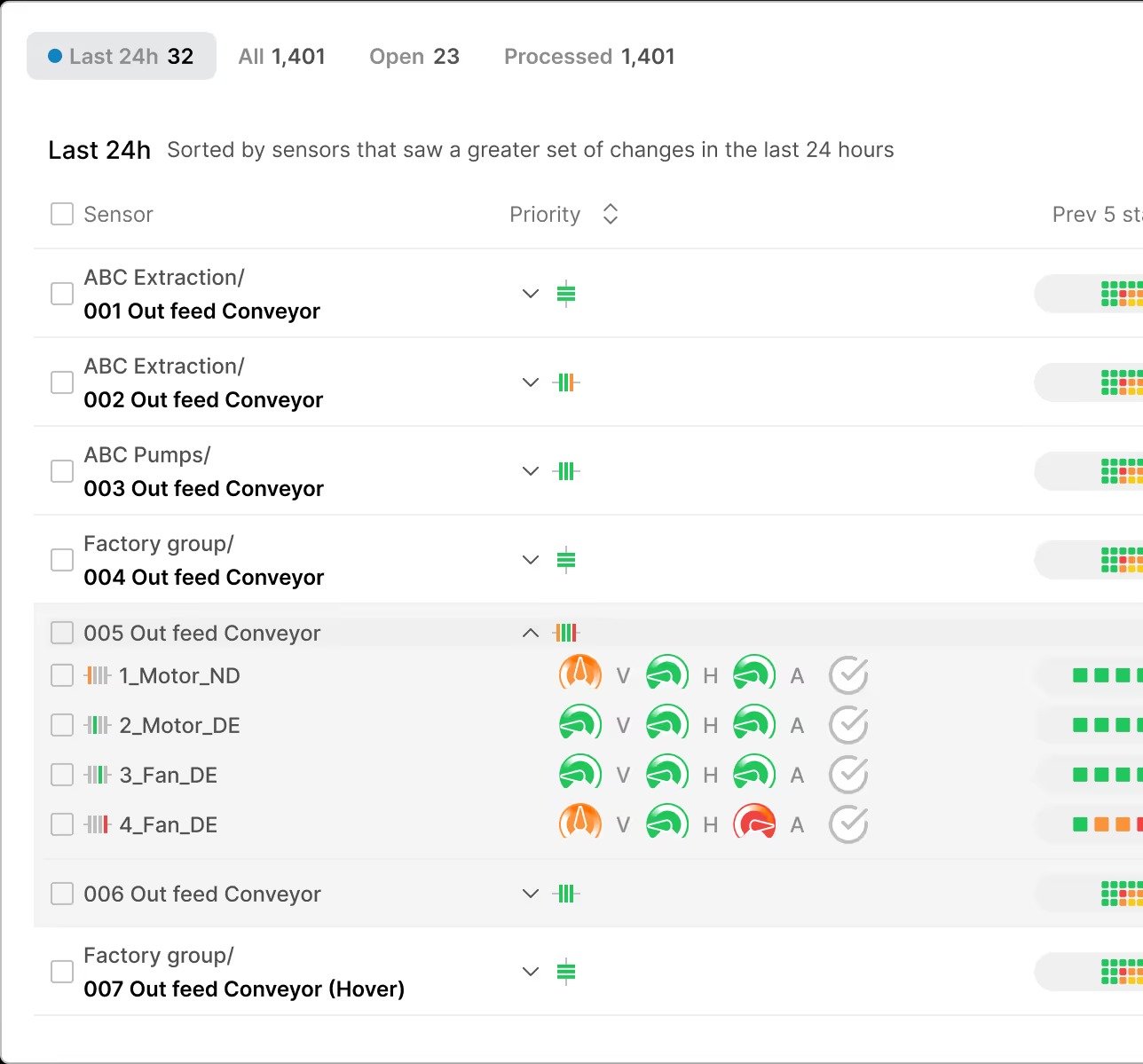

Wireless vibration monitoring systems are designed to address the dynamic challenges of industrial operations. They combine high-precision sensors with secure connectivity to deliver actionable data on equipment performance. Features like AI-driven analytics, real-time alerts, and seamless integration with existing systems empower teams to identify potential issues before they escalate. These tools improve safety, reduce maintenance costs, and ensure uninterrupted productivity.

- Wireless Connectivity: Secure, long-range data transmission for remote monitoring.

- Real-Time Alerts: Instant notifications for vibration anomalies.

- AI-Driven Insights: Advanced analytics for predictive maintenance.

- Scalable Design: Supports plants of all sizes and complexities. Energy Efficient: Low-power sensors for extended operation.

- Seamless Integration: Easily integrates with SCADA and ERP systems.

FAQs

FAQs

Manufacturing, energy, and process industries rely on them for predictive maintenance.

Yes, these systems are designed for flexible deployment.

Absolutely, they leverage AI for actionable maintenance insights.

Yes, they seamlessly connect with SCADA, ERP, and IoT platforms.

By identifying potential failures early, they reduce risk and ensure equipment reliability.