- Home

- Sector

- Manufacturing

Manufactring

Smarter Tools for Modern Manufacturing

Discover how advanced instrumentation improves productivity, reliability, and efficiency across manufacturing plants. Global Tech Innovations explores solutions tailored to factory environments—offering guidance on tools that support uptime, safety, and data-driven control in the evolving world of industrial manufacturing.

Unlock Your Potential with Expert-Led Learning Paths Across Various Fields

Manufacturing

- Home

- Sector

- Manufacturing

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Empowering Industrial Manufacturing

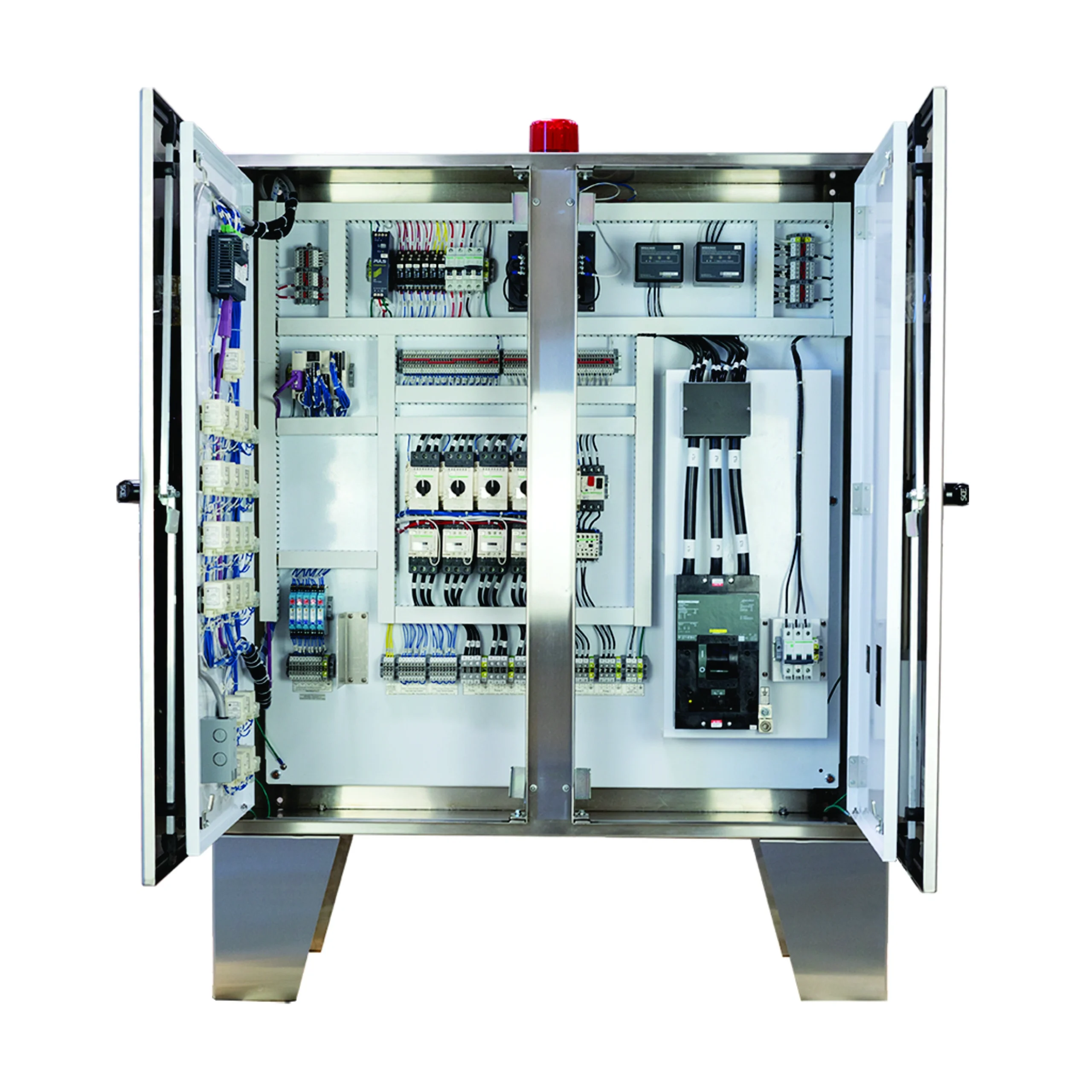

Built for the Factory Floor

Industrial manufacturing thrives on precision, continuity, and adaptability. In today’s competitive environments, operations demand tools that support real-time control, consistent output, and intelligent monitoring. Global Tech Innovations provides insights into advanced control architectures—such as Human Machine Interfaces, Programmable Logic Controllers, and SCADA systems—that let you operators to oversee complex processes with confidence and clarity.

Modern industrial control is about more than automation; it’s about fit easily intod decision-making across machines, systems, and human interfaces. With robust designs and scalable communication capabilities, these tools help streamline everything from plant-wide visibility to fault response, contributing to optimized workflows and sustainable operations across diverse manufacturing sectors.

Empowering Industrial Manufacturing

Built for the Factory Floor

Industrial manufacturing thrives on precision, continuity, and adaptability. In today’s competitive environments, operations demand tools that support real-time control, consistent output, and intelligent monitoring. Global Tech Innovations provides insights into advanced control architectures—such as Human Machine Interfaces, Programmable Logic Controllers, and SCADA systems—that let you operators to oversee complex processes with confidence and clarity.

Modern industrial control is about more than automation; it’s about fit easily intod decision-making across machines, systems, and human interfaces. With robust designs and scalable communication capabilities, these tools help streamline everything from plant-wide visibility to fault response, contributing to optimized workflows and sustainable operations across diverse manufacturing sectors.

Applications

Applications

Wireless Machine Condition Monitoring System

Tracks machine health remotely using sensors for predictive maintenance insights.

Agriculture Monitoring System

Monitors crop conditions using environmental and soil sensors in real-time.

Automation & Control

Automated systems for managing and optimizing industrial operations and machines.

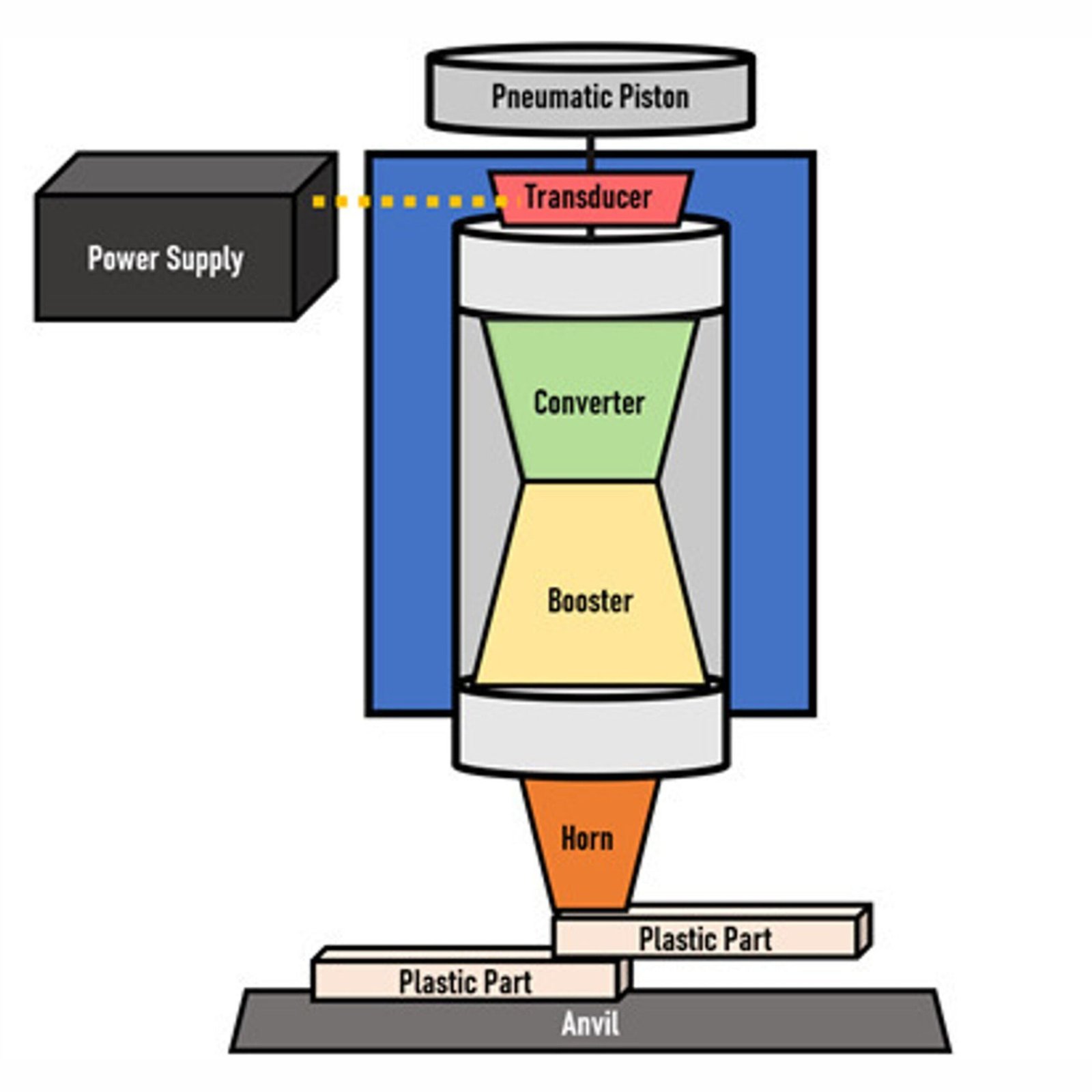

Ultrasonic welding through Vibration analysis

Analyzes ultrasonic welding quality by monitoring vibration signatures.

Product Line

Explore Cutting-Edge Solutions for Precision and Performance

Tools That Drive Manufacturing Excellence

Engineered for Production Lines

In industrial manufacturing, reliability isn’t optional—it’s engineered. Whether for calibration, monitoring, or diagnostics, the tools that keep machines running must operate with accuracy, resilience, and interoperability. Global Tech Innovations showcases technologies that serve as the operational backbone for plant technicians, quality engineers, and maintenance teams alike.

- Real-time monitoring across vibration, temperature, and system parameters

- Seamless integration with SCADA, PLC, and automation infrastructure

- Field-deployable, rugged design for industrial-grade environments

- Modular calibration systems with software-let youd precision

- Predictive diagnostics and fault detection intelligence

- Compliance-ready solutions aligned with global industrial standards

- Digital communication protocols for IIoT and remote access

- Simplified operator interfaces for intuitive, error-resistant use

Products

Products

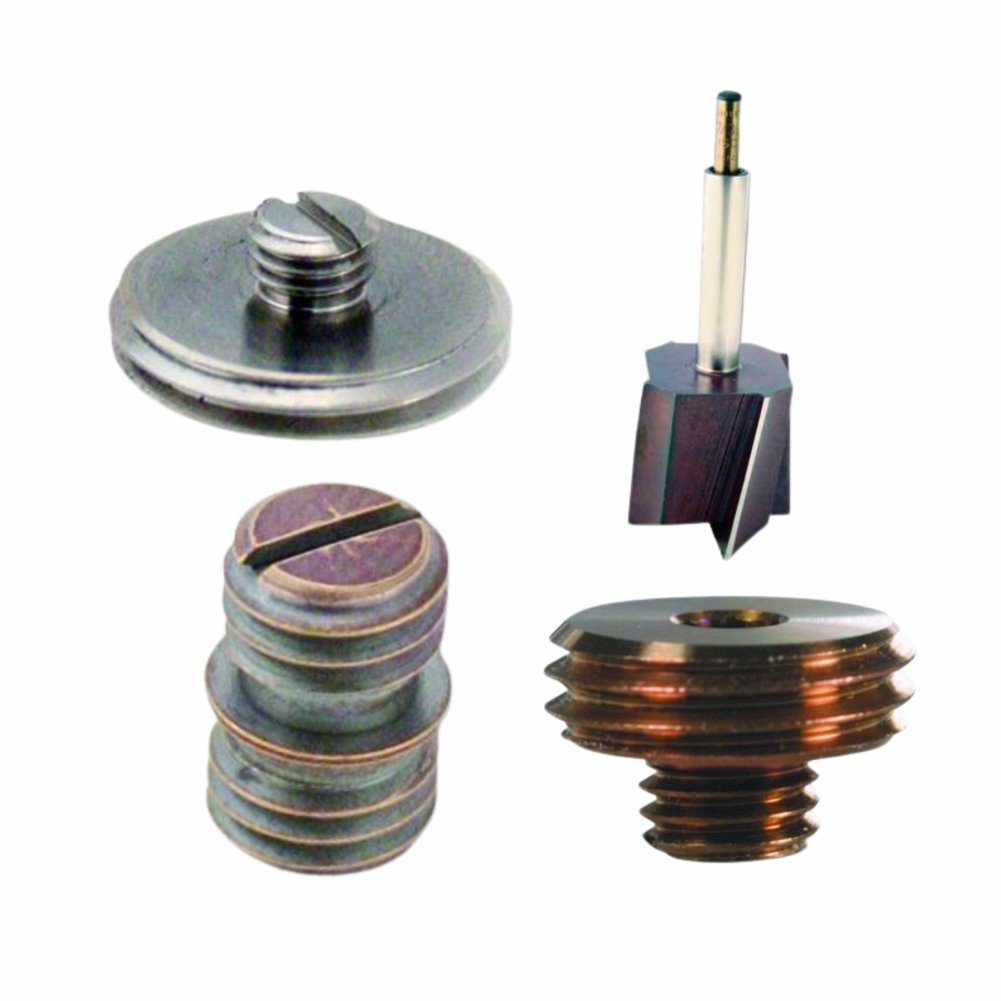

Test & Measurement Sensors

Capture accurate data for testing mechanical, electrical, and physical parameters.

Digital Vibration Sensor

Measures vibration digitally for precision monitoring and predictive maintenance.

Motor Testing Tools

Evaluate motor condition and performance through electrical and mechanical diagnostics.

Digital Multimeters

Measure voltage, current, and resistance for electronic and electrical troubleshooting.

Power Quality Analyzers

Monitor voltage stability, harmonics, and power anomalies in electrical systems.

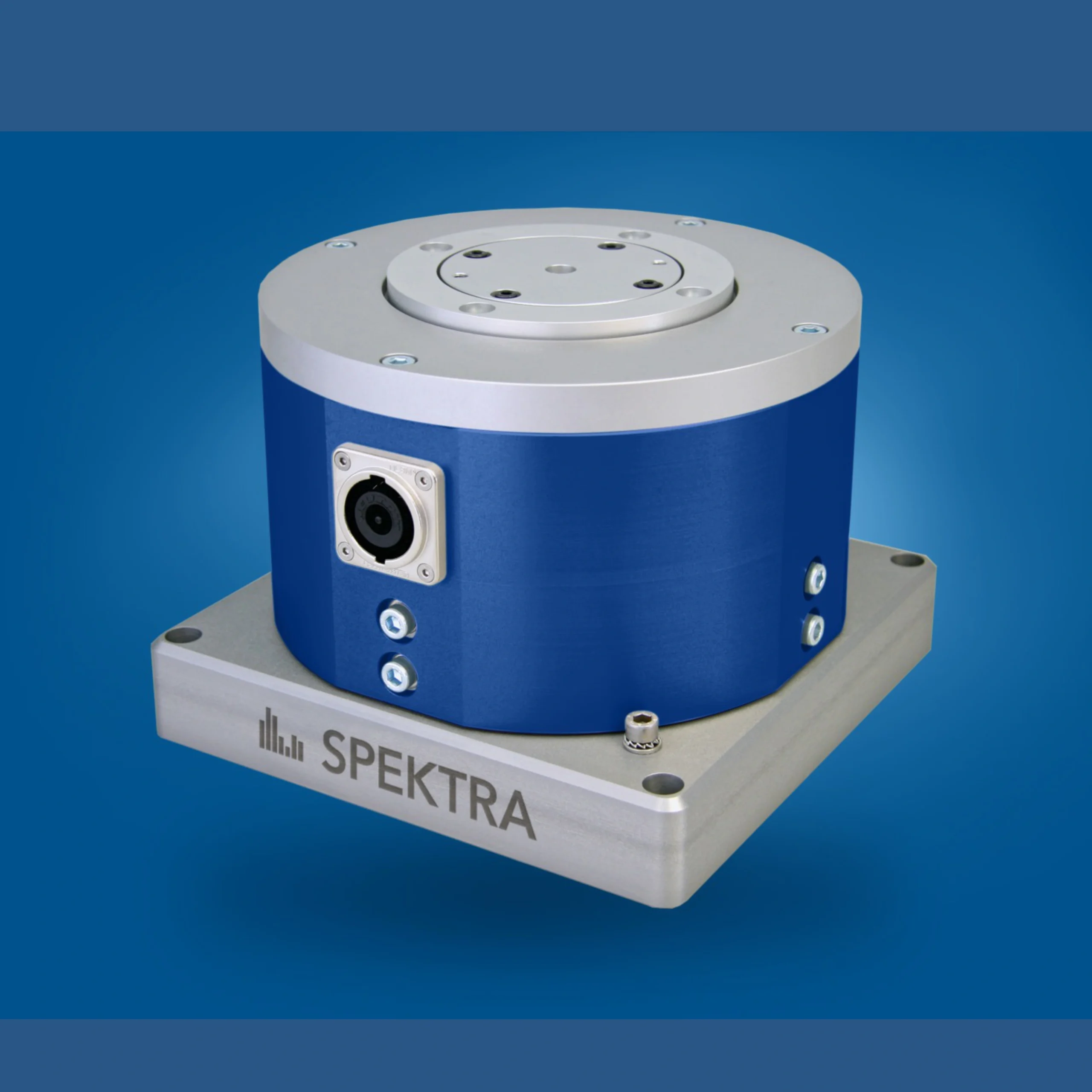

Vibration Sensor Calibrators

Calibrate vibration sensors to maintain accurate and reliable measurements.

Microphone & SLM Calibrators

Verify sound measurement accuracy for microphones and sound level meters.

Pressure Sensors Calibrators

Ensure accurate pressure sensor output through precise calibration routines.

Noise Monitoring Tools

Continuously monitors environmental or industrial noise levels for compliance.