- Home

- Sector

- Fertlizer

Fertlizer

Safe, Stable, Smart

Global Tech Innovations supports the fertilizer industry with precision monitoring and automation tools engineered to keep production lines running efficiently—protecting equipment, personnel, and product quality even in highly reactive or corrosive operating environments.

Unlock Your Potential with Expert-Led Learning Paths Across Various Fields

Fertlizer

- Home

- Sector

- Fertlizer

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Intelligent Systems for Fertilizer Processing

Designed for Plant Flow

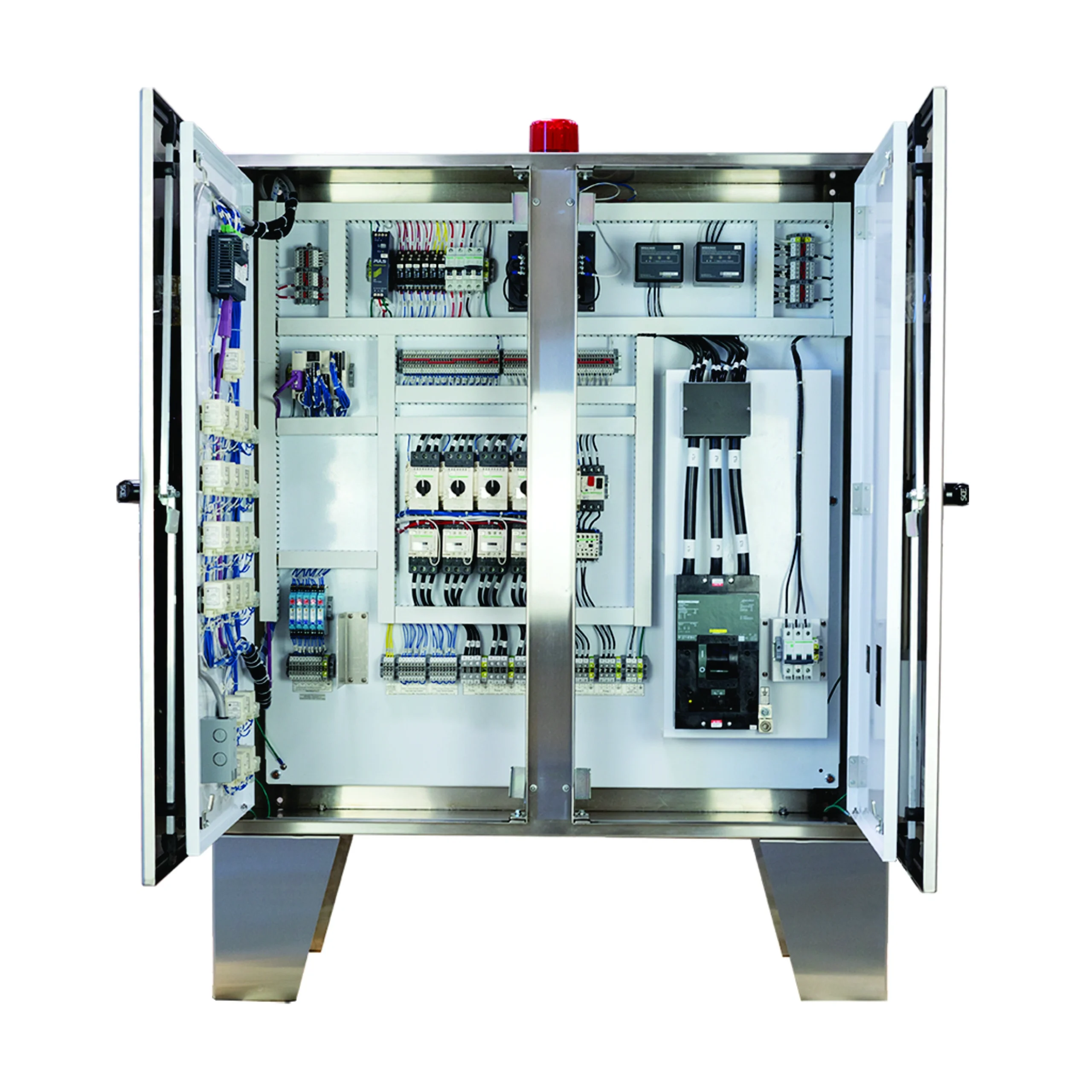

In the fertilizer manufacturing sector, precise control and equipment reliability are central to consistent product quality and safety. Global Tech Innovations highlights technology solutions that support process efficiency and environmental compliance through advanced sensors, automation modules, and condition monitoring systems. These tools help maintain consistent flow control, detect early-stage machinery faults, and optimize energy use in rotary dryers, granulators, mixers, and packaging lines.

By integrating smart instrumentation across various stages of production—from raw material dosing to bagging—manufacturers gain real-time visibility into operations. This leads to more stable chemical reactions, reduced equipment stress, and improved uptime. In harsh environments with corrosive vapors or abrasive solids, rugged sensors and diagnostic tools play a critical role in preserving machinery health and minimizing process disruptions.

Intelligent Systems for Fertilizer Processing

Designed for Plant Flow

In the fertilizer manufacturing sector, precise control and equipment reliability are central to consistent product quality and safety. Global Tech Innovations highlights technology solutions that support process efficiency and environmental compliance through advanced sensors, automation modules, and condition monitoring systems. These tools help maintain consistent flow control, detect early-stage machinery faults, and optimize energy use in rotary dryers, granulators, mixers, and packaging lines.

By integrating smart instrumentation across various stages of production—from raw material dosing to bagging—manufacturers gain real-time visibility into operations. This leads to more stable chemical reactions, reduced equipment stress, and improved uptime. In harsh environments with corrosive vapors or abrasive solids, rugged sensors and diagnostic tools play a critical role in preserving machinery health and minimizing process disruptions.

Applications

Applications

Wireless Machine Condition Monitoring System

Tracks machine health remotely using sensors for predictive maintenance insights.

Impact Hammer Modal Testing System

Measures structural response to impact for modal analysis studies.

Product Line

Explore Cutting-Edge Solutions for Precision and Performance

Maintenance-Ready Solutions for Harsh Conditions

Built for Corrosive Duty

Global Tech Innovations identifies technologies that align with the fertilizer industry’s demand for precision and durability. These tools are engineered to withstand chemical exposure, dust-heavy environments, and fluctuating temperatures—common across most fertilizer plants.

- Corrosion-Resistant Sensors: For monitoring flow, pressure, and vibration in chemical zones.

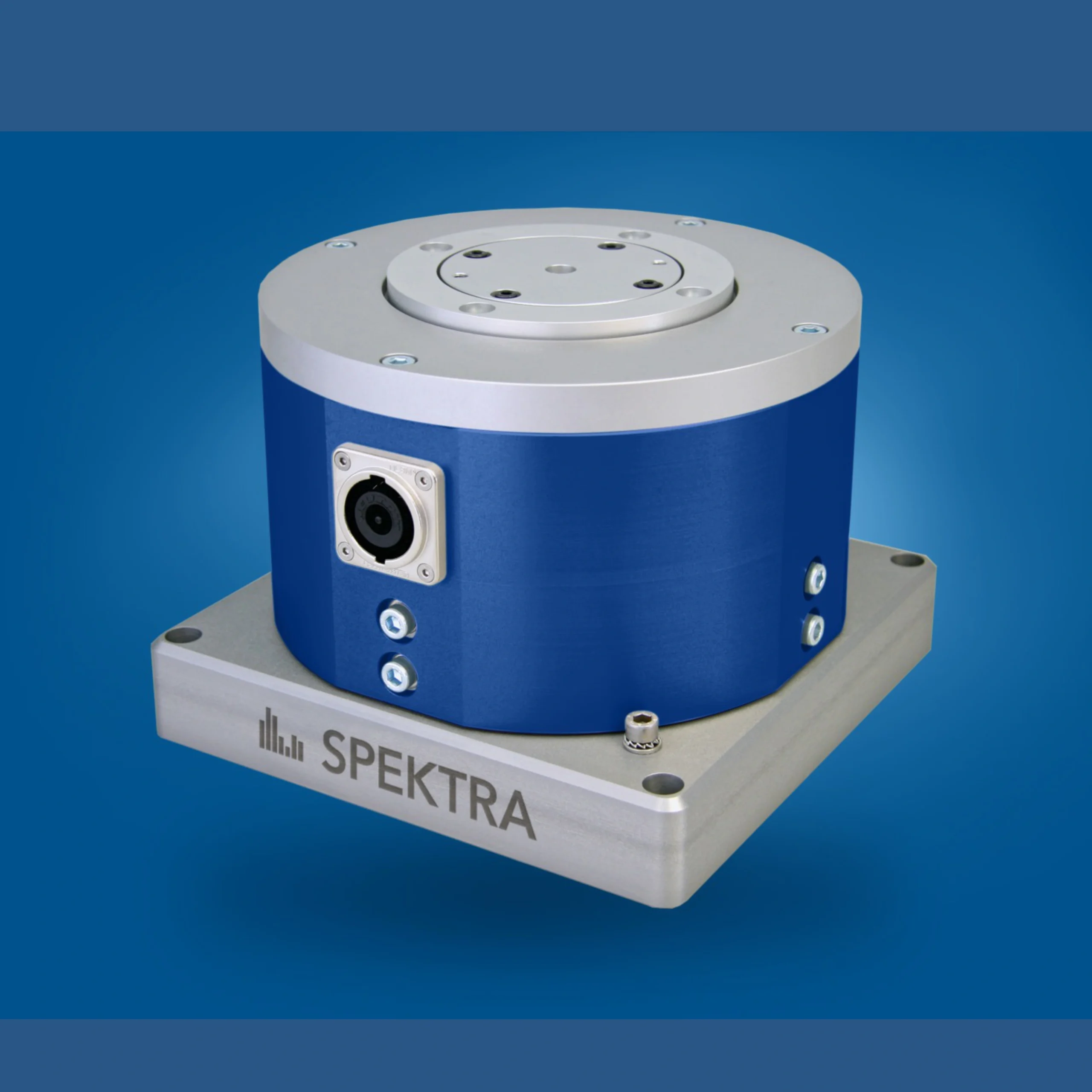

- Digital Vibration Transmitters: Provide continuous machinery health data with smart fault alerts.

- 4–20 mA Loop Devices: Ensure seamless integration with PLCs and DCS for process control.

- Laser Vibrometry Systems: Non-contact inspection for structural fatigue in rotating drums.

- Condition Monitoring Tools: Detect imbalance, looseness, and misalignment in pumps and agitators.

- Automation Modules: Support dosing accuracy, conveyor timing, and closed-loop feedback.

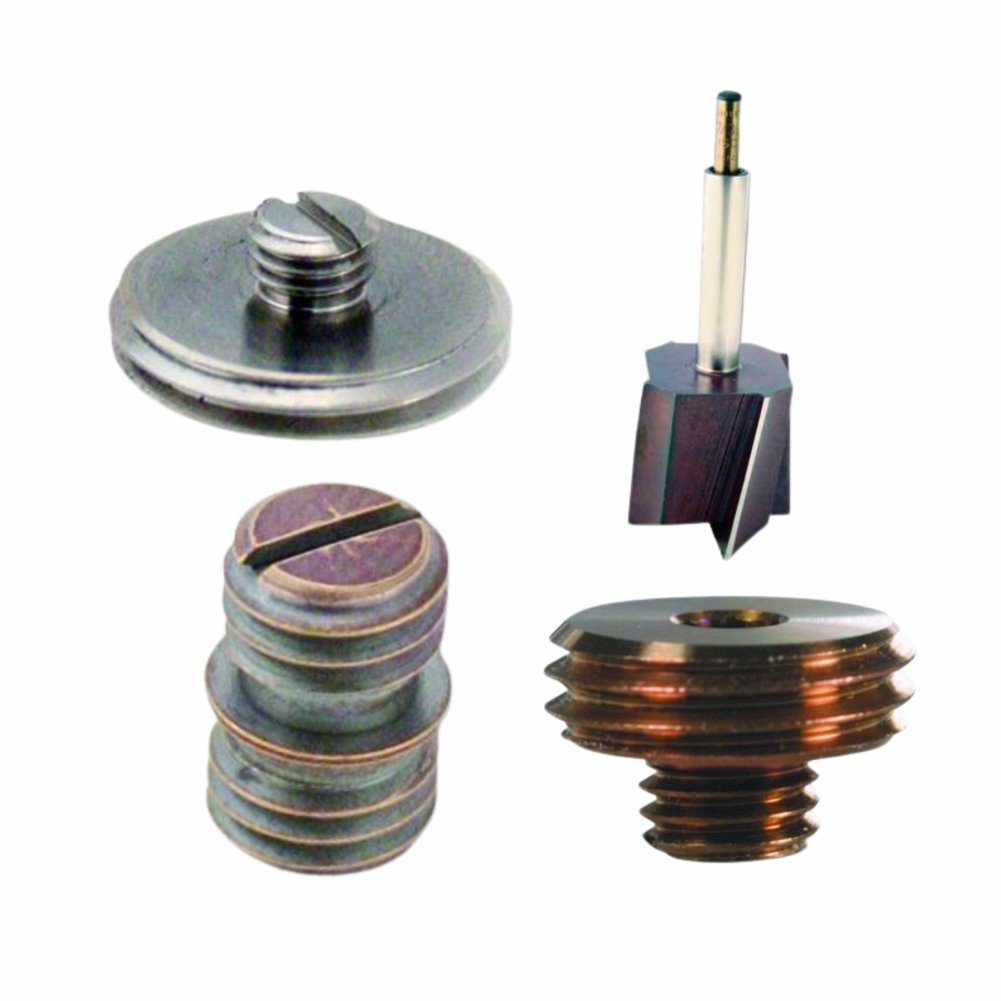

- Sensor Enclosures & Accessories: IP-rated housings and magnetic mounts improve safety and accessibility.

Products

Products

Test & Measurement Sensors

Capture accurate data for testing mechanical, electrical, and physical parameters.

Digital Vibration Sensor

Measures vibration digitally for precision monitoring and predictive maintenance.

Motor Testing Tools

Evaluate motor condition and performance through electrical and mechanical diagnostics.

Digital Multimeters

Measure voltage, current, and resistance for electronic and electrical troubleshooting.

Power Quality Analyzers

Monitor voltage stability, harmonics, and power anomalies in electrical systems.

Vibration Sensor Calibrators

Calibrate vibration sensors to maintain accurate and reliable measurements.

Microphone & SLM Calibrators

Verify sound measurement accuracy for microphones and sound level meters.

Pressure Sensors Calibrators

Ensure accurate pressure sensor output through precise calibration routines.

Noise Monitoring Tools

Continuously monitors environmental or industrial noise levels for compliance.