- Home

- Sector

- Aerospace & Defence Industry

Aerospace & Defence Industry

Test and Sensing Solutions for Aerospace Systems

Discover high-performance test instrumentation and sensing solutions tailored to the aerospace and defence industries. Global Tech Innovations highlights advanced tools that deliver precision data in high-dynamic, mission-critical applications—from structural vibration to propulsion diagnostics.

Unlock Your Potential with Expert-Led Learning Paths Across Various Fields

Aerospace & Defence Industry

- Home

- Sector

- Aerospace & Defence Industry

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Precision Testing in Aerospace & Defence

Engineered for Flight Readiness

In aerospace and defence, precision isn’t a luxury—it’s a lifeline. Every component, system, and structure must meet stringent performance expectations under extreme stress, motion, and environmental exposure. Global Tech Innovations explores instrumentation tools built to support advanced vibration testing, modal analysis, and structural diagnostics required in these high-stakes industries.

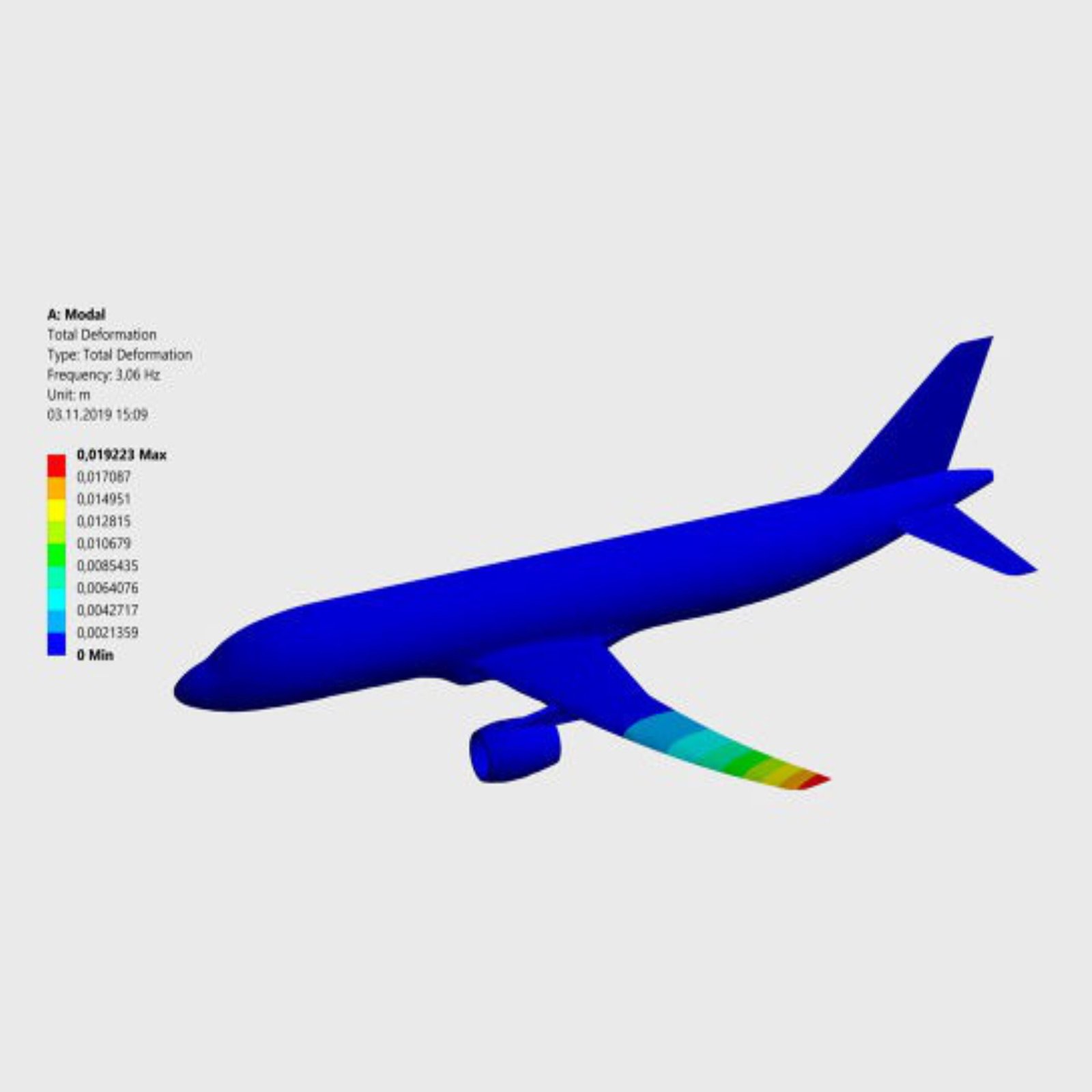

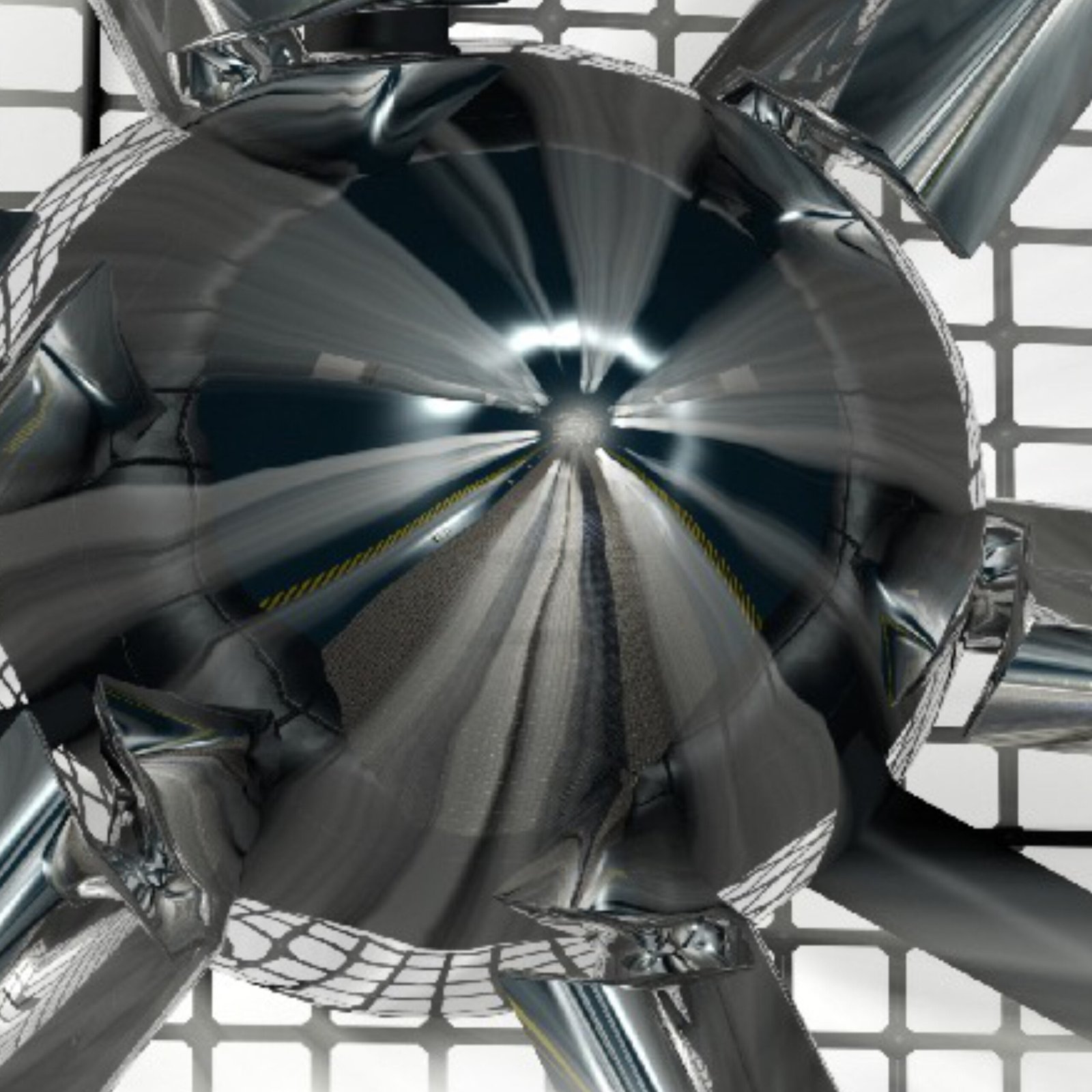

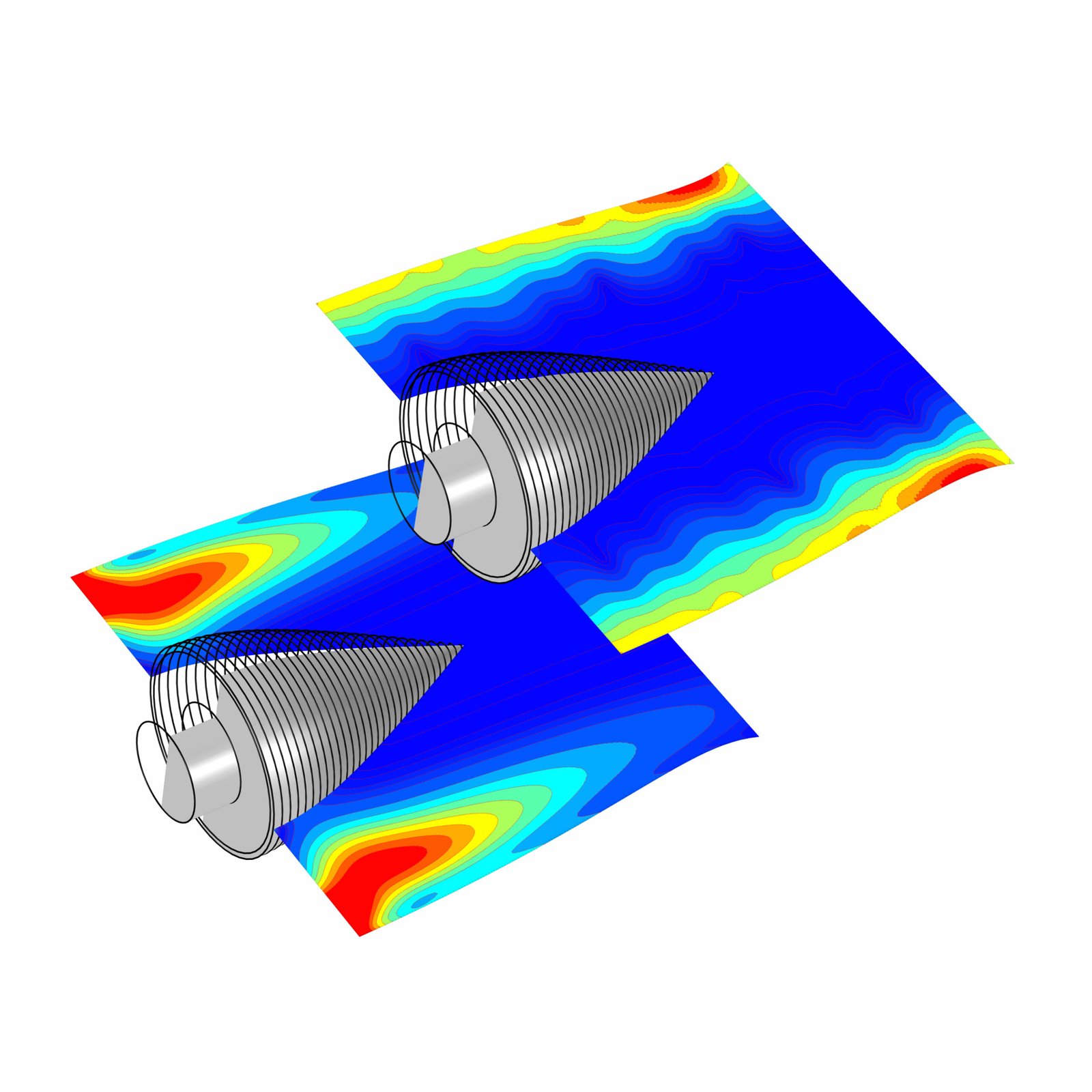

From testing jet engine components to evaluating missile systems, vibration analysis technologies like laser vibrometry provide non-contact, high-resolution insight into mechanical integrity. These tools help engineers identify resonance, fatigue, and structural instabilities before they become critical risks. Combined with high-performance sensors and diagnostics platforms, these technologies let you teams to validate designs, optimize material performance, and maintain safety standards across mission-critical equipment.

Precision Testing in Aerospace & Defence

Engineered for Flight Readiness

In aerospace and defence, precision isn’t a luxury—it’s a lifeline. Every component, system, and structure must meet stringent performance expectations under extreme stress, motion, and environmental exposure. Global Tech Innovations explores instrumentation tools built to support advanced vibration testing, modal analysis, and structural diagnostics required in these high-stakes industries.

From testing jet engine components to evaluating missile systems, vibration analysis technologies like laser vibrometry provide non-contact, high-resolution insight into mechanical integrity. These tools help engineers identify resonance, fatigue, and structural instabilities before they become critical risks. Combined with high-performance sensors and diagnostics platforms, these technologies let you teams to validate designs, optimize material performance, and maintain safety standards across mission-critical equipment.

Applications

Applications

Gun Barrel Testing System

Inspects internal barrel structure for defects using non-destructive testing.

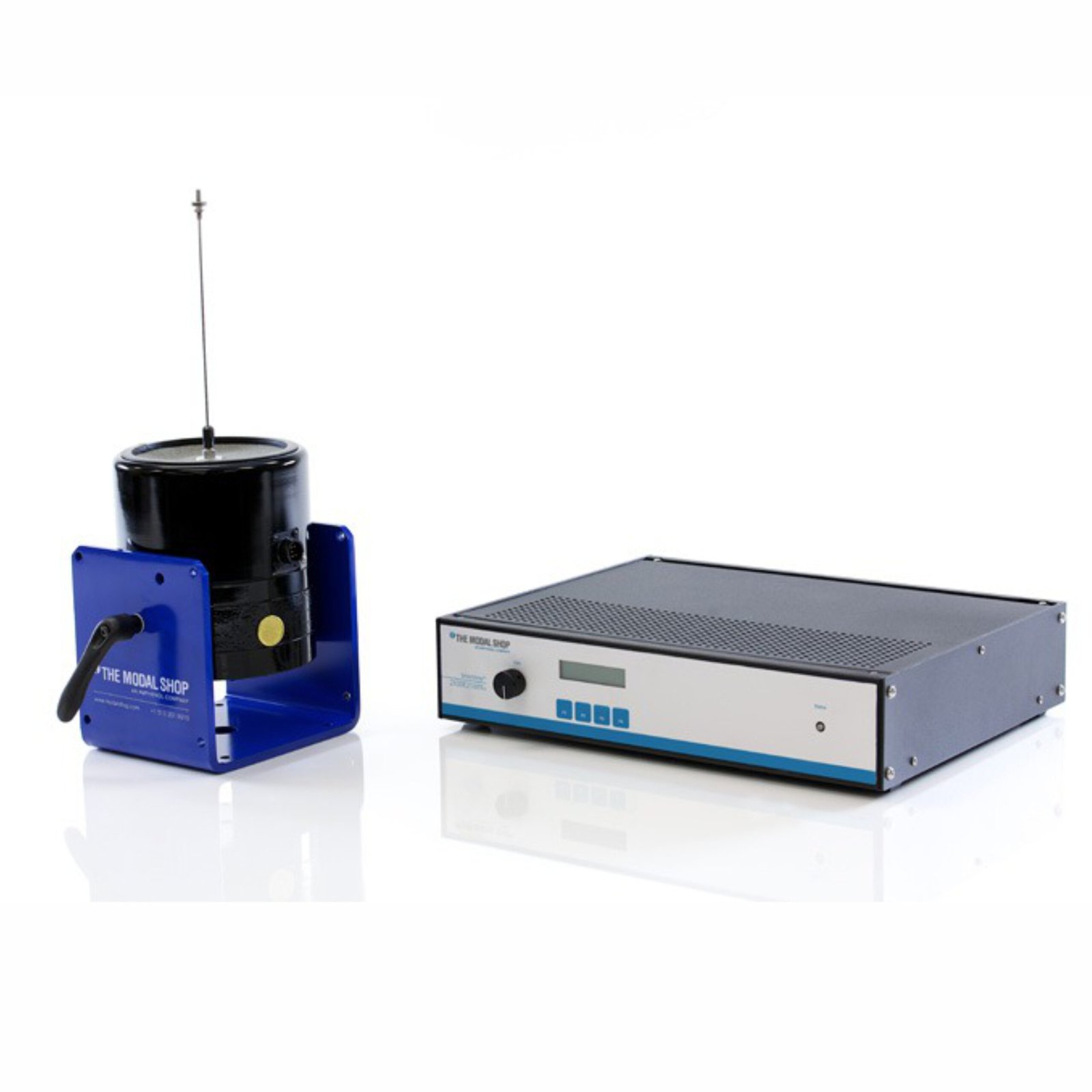

Impact Hammer Modal Testing System

Measures structural response to impact for modal analysis studies.

Modal Shaker Testing System

Applies controlled force to study a structure’s vibrational characteristics.

Space Cube Testing

Tests aerospace components under simulated space conditions and environmental stress.

Analysis of wing vibrations

Studies aircraft wing vibration behavior under aerodynamic and structural loads.

Precise vibration analysis in the wind tunnel

Studies aircraft wing vibration behavior under aerodynamic and structural loads.

Testing riveted joints with laser vibrometry

Assesses structural joint integrity using laser-based vibration measurements.

Product Line

Explore Cutting-Edge Solutions for Precision and Performance

Advanced Tools for Aerospace Measurement

Built for Mission Demands

Aerospace and defence sectors demand tools that deliver speed, accuracy, and reliability. Global Tech Innovations helps you access measurement systems and sensor technologies that elevate test capability in high-energy, dynamic environments.

- Non-contact laser vibrometry for high-speed vibration profiling

- Modular 3D scanning for full-surface aerospace component testing

- Digital accelerometers for real-time structural health data

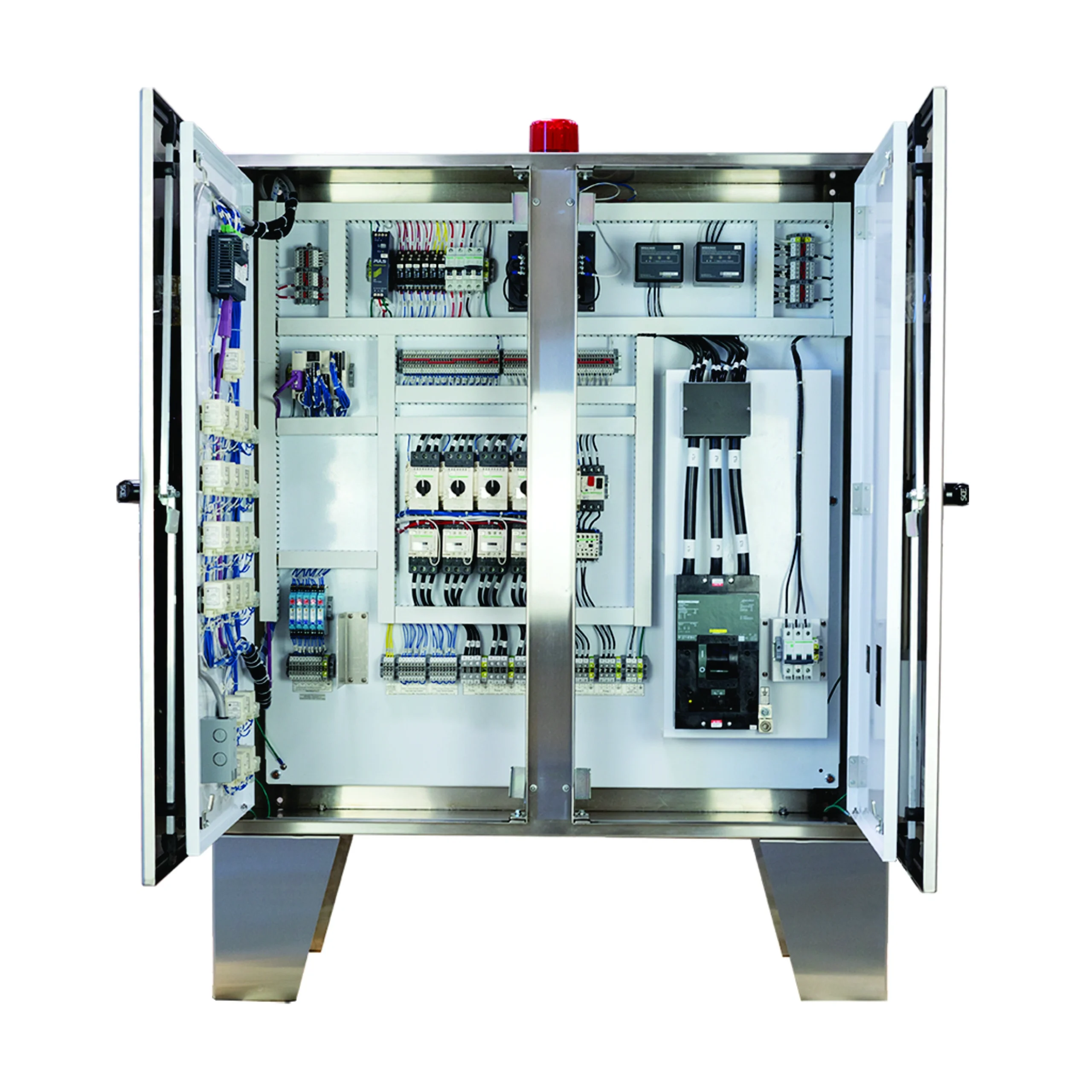

- Ruggedized sensors and electronics designed for shock and temperature extremes

- Ballistic and combustion pressure sensors with rapid rise-time capability

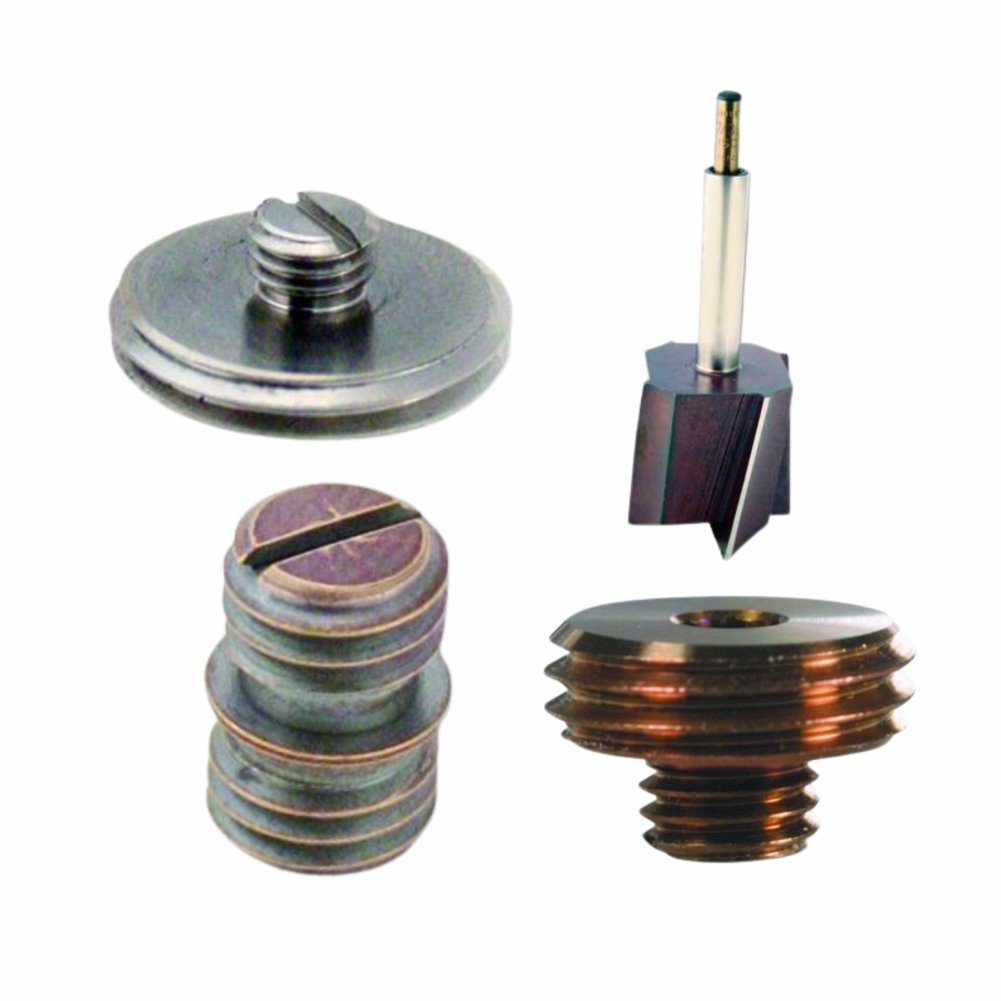

- ISO-calibrated strain and force sensors for critical material feedback

- Seamless integration into aerospace-grade data acquisition systems

- Remote-access systems helping field testing and live monitoring

Products

Products

Test & Measurement Sensors

Capture accurate data for testing mechanical, electrical, and physical parameters.

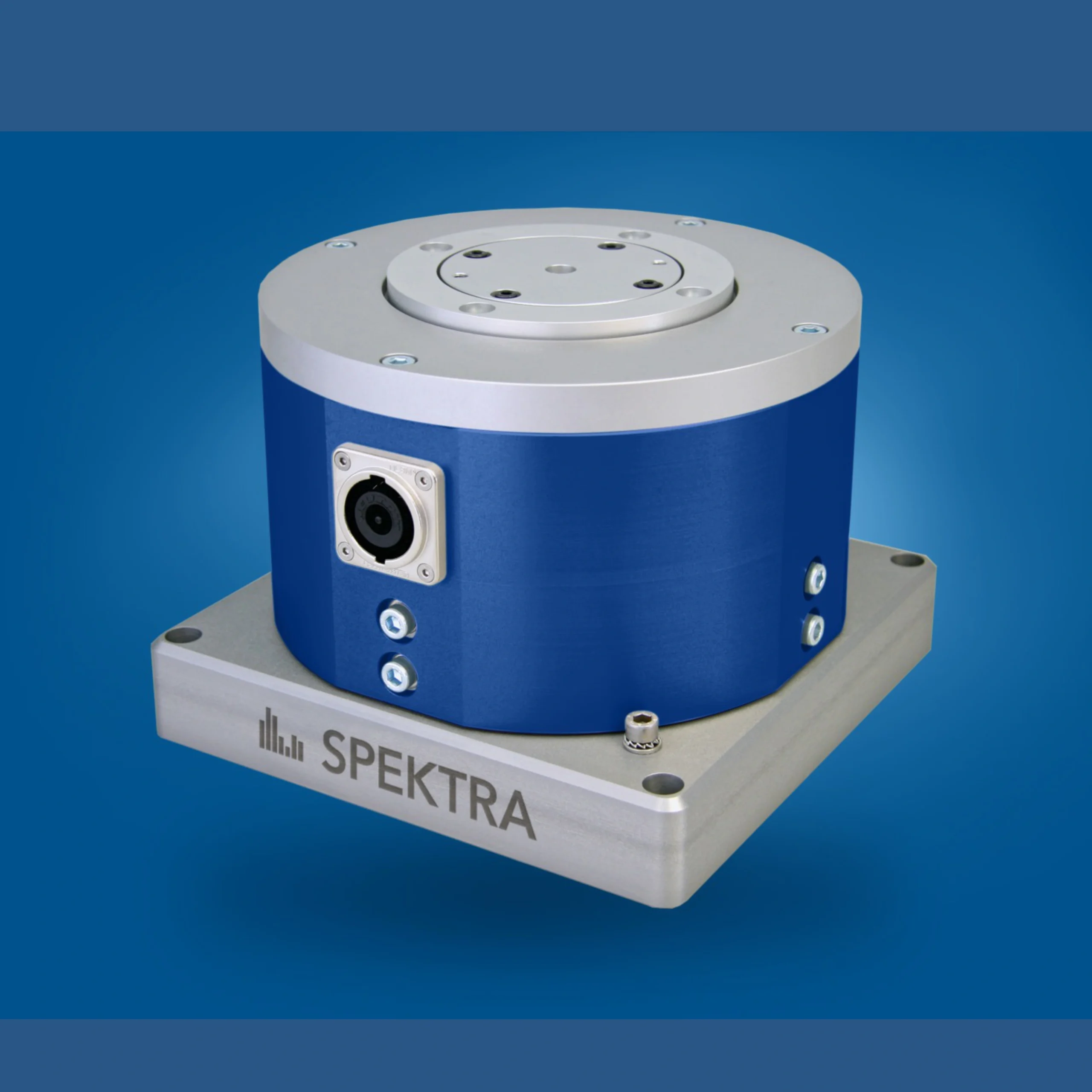

Digital Vibration Sensor

Measures vibration digitally for precision monitoring and predictive maintenance.

Digital Multimeters

Measure voltage, current, and resistance for electronic and electrical troubleshooting.

Power Quality Analyzers

Monitor voltage stability, harmonics, and power anomalies in electrical systems.

Vibration Sensor Calibrators

Calibrate vibration sensors to maintain accurate and reliable measurements.

Microphone & SLM Calibrators

Verify sound measurement accuracy for microphones and sound level meters.

Pressure Sensors Calibrators

Ensure accurate pressure sensor output through precise calibration routines.

Noise Monitoring Tools

Continuously monitors environmental or industrial noise levels for compliance.