Torque Transducers

High-precision torque sensors for rotating and reaction measurement in demanding applications.

Engineered for durability, speed, and integration with industrial monitoring systems.

Torque Transducers

Precision Torque Measurement for Diverse Industrial Applications

Global Tech Innovations provides high-accuracy torque transducers designed to convert mechanical torque into precise electrical signals for measurement, monitoring, and control. These sensors are ideal for applications including electric motor testing, dynamometer systems, pump and fan performance evaluation, and automotive drivetrain diagnostics. Built on strain gage-based Wheatstone Bridge technology, our torque sensors offer reliable torque feedback even in high-vibration and high-speed environments. They are essential for assessing mechanical efficiency, load balance, and torque-to-speed relationships in complex systems.

Torque Transducers

Precision Torque Measurement for Diverse Industrial Applications

Global Tech Innovations provides high-accuracy torque transducers designed to convert mechanical torque into precise electrical signals for measurement, monitoring, and control. These sensors are ideal for applications including electric motor testing, dynamometer systems, pump and fan performance evaluation, and automotive drivetrain diagnostics. Built on strain gage-based Wheatstone Bridge technology, our torque sensors offer reliable torque feedback even in high-vibration and high-speed environments. They are essential for assessing mechanical efficiency, load balance, and torque-to-speed relationships in complex systems.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

Reliable Torque Measurement Solutions

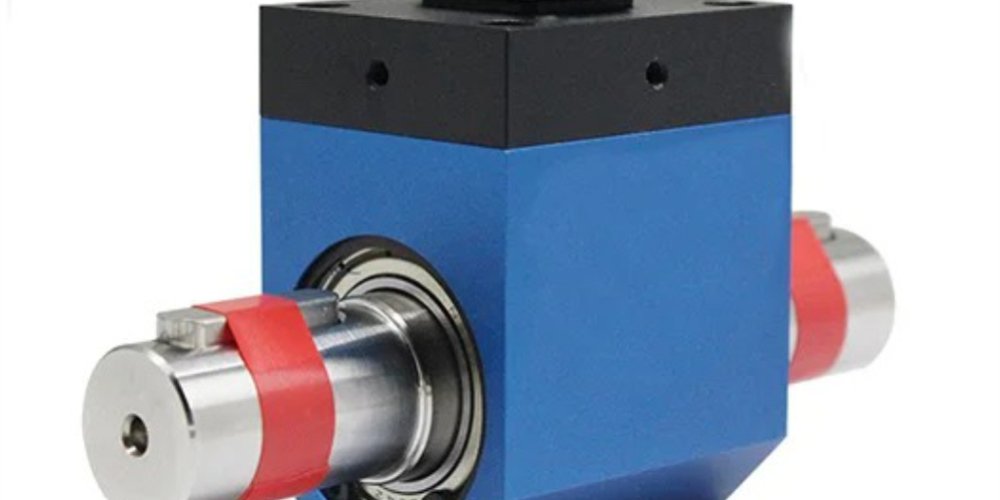

Wide Range of Sensor Types with Industrial-Grade Durability

We offer a complete portfolio of torque transducers, including rotary slip ring, rotary transformer, reaction torque sensors, and TORKDISC® in-line models. These options cover both rotating and non-rotating applications, supporting high RPM ratings, torsional stiffness, and continuous-duty operation. Designed for integration into industrial control systems, these transducers are available with analog or digital output and are compatible with standard signal conditioners and data acquisition systems. Rugged construction ensures durability under continuous mechanical stress, making them well-suited for harsh environments such as test stands, production floors, and field monitoring.

- Strain gage-based sensing for high-accuracy torque measurement

- Available in rotary, slip ring, reaction, and in-line TORKDISC® formats

- Designed for high RPM and torsional rigidity in rotating systems

- Suitable for motor, brake, pump, and fan performance testing

- Rugged construction for durability in industrial applications

- Compatible with standard DAQ systems and signal conditioners

Sectors

Sectors

Fertlizer

Systems ensuring quality control, safety, and environmental monitoring in fertilizer…

Learn MoreAutomotive

Testing and diagnostic tools for automotive performance, safety, and durability…

Learn MoreOil & Gas

Monitoring, testing, and automation systems for exploration and refinery operations.

Learn MoreConstruction Industry

Tools for structural monitoring, safety testing, and environmental condition measurement.

Learn MoreAerospace & Defence Industry

Advanced tools for testing and monitoring aerospace and defense applications.

Learn MoreManufacturing

Industrial production processes optimized using automation, testing, and monitoring technologies.

Learn MoreFAQs

FAQs

They are used to measure rotational force in systems such as electric motors, pumps, gearboxes, and automotive components, helping monitor efficiency and mechanical performance.

Rotary sensors measure torque on a rotating shaft, while reaction sensors are stationary and often used when rotation isn't required—offering a more cost-effective solution.

Yes. Our torque transducers are compatible with most DAQ systems and can output analog or digital signals for easy integration into monitoring and control setups.

Absolutely. They're built with industrial-grade materials and torsional rigidity to withstand harsh conditions and long-term usage.