Strain Sensor

High-performance piezoelectric strain sensors for accurate, real-time stress monitoring.

Compact, rugged design ensures easy integration in harsh industrial and research environments.

Strain Sensor

Precision Measurement with Quartz Piezoelectric Technology

Global Tech Innovations offers high-performance strain sensors engineered for precise, linear measurement of strain in industrial and research environments. These sensors are ideal for monitoring mechanical stress in press systems, machinery frames, rotating equipment, and advanced material testing applications. Unlike traditional strain gages, our piezoelectric strain sensors maintain stable mV/microstrain sensitivity across the full measurement range, ensuring accurate and repeatable results—even under extreme stress or dynamic loads. These sensors are particularly well-suited for applications where fast response, high resolution, and low maintenance are required.

Strain Sensor

Precision Measurement with Quartz Piezoelectric Technology

Global Tech Innovations offers high-performance strain sensors engineered for precise, linear measurement of strain in industrial and research environments. These sensors are ideal for monitoring mechanical stress in press systems, machinery frames, rotating equipment, and advanced material testing applications. Unlike traditional strain gages, our piezoelectric strain sensors maintain stable mV/microstrain sensitivity across the full measurement range, ensuring accurate and repeatable results—even under extreme stress or dynamic loads. These sensors are particularly well-suited for applications where fast response, high resolution, and low maintenance are required.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

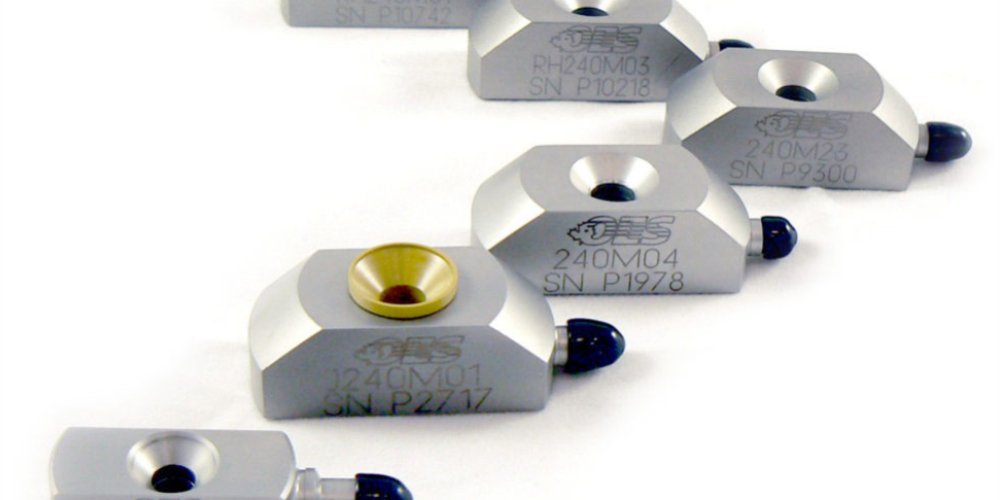

Durable Strain Sensing Solutions

Robust Construction and Easy Integration for Harsh Environments

Our strain sensors are built for durability in demanding environments, offering reliable performance in high-vibration, high-temperature, or corrosive conditions. They can be installed easily using a single bolt screw or adhesive mount, making them a practical choice for both temporary testing and permanent monitoring setups. With robust housing and compact form factors, these sensors can be integrated into control systems, structural health monitoring platforms, or R&D instrumentation. Their superior linearity, rugged construction, and compatibility with industrial signal conditioners make them a trusted solution for engineers and technicians seeking consistent performance and accurate control feedback.

- Consistent mV/μstrain sensitivity across full operating range

- Quartz piezoelectric sensing technology for fast, accurate response

- Non-invasive installation using adhesive or single-screw mounting

- Suitable for high-vibration and high-temperature environments

- Ideal for structural monitoring, press force control, and R&D

- Compatible with industrial signal conditioning and DAQ systems

Sectors

Sectors

Fertlizer

Systems ensuring quality control, safety, and environmental monitoring in fertilizer…

Learn MoreAutomotive

Testing and diagnostic tools for automotive performance, safety, and durability…

Learn MoreOil & Gas

Monitoring, testing, and automation systems for exploration and refinery operations.

Learn MoreConstruction Industry

Tools for structural monitoring, safety testing, and environmental condition measurement.

Learn MoreAerospace & Defence Industry

Advanced tools for testing and monitoring aerospace and defense applications.

Learn MoreManufacturing

Industrial production processes optimized using automation, testing, and monitoring technologies.

Learn MoreFAQs

FAQs

Strain sensors are used to measure mechanical deformation in structures and equipment, helping monitor load, stress, or pressure during operation.

Unlike strain gages, our sensors provide consistent linear output without sensitivity loss at the extremes of the range and require less signal conditioning.

Yes. With adhesive or bolt-mount options, installation is fast and non-invasive, making them ideal for permanent or temporary use.

Absolutely. They are designed to withstand challenging industrial environments involving vibration, heat, or corrosion.