Brake & Switch Crossing Measurement Tools

Reliable Measurement Tools for Rail Brake and Switch Diagnostics.

Enhance Safety, Reduce Downtime, and Enable Predictive Maintenance.

Brake & Switch Crossing Measurement Tools

Precision Tools for Brake and Switch Crossing Measurements

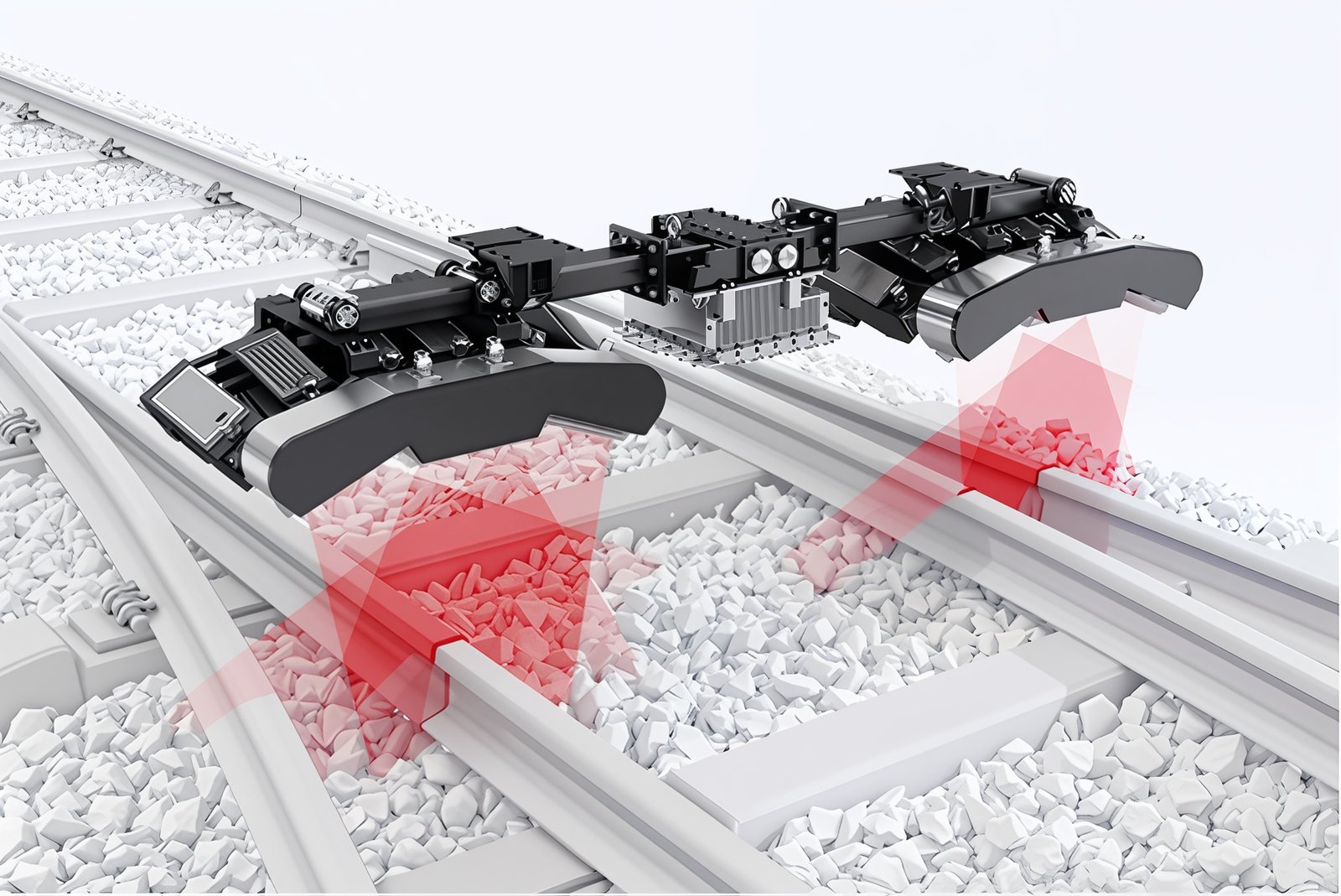

We offer advanced Brake and Switch Crossing Measurement Tools designed for accurate, repeatable, and efficient data collection on rail infrastructure. These specialized systems help rail operators and infrastructure managers ensure safe and compliant railway operations by measuring dynamic and static parameters on brake forces, track geometry, and switch crossing wear. Greenwood’s innovative approach supports real-time data acquisition, reduced downtime, and predictive maintenance across a variety of rail networks.

Used by leading infrastructure operators worldwide, these tools provide essential data for condition-based maintenance planning. We combine rugged hardware with intelligent software interfaces, enabling operators to analyze trends, identify irregularities, and extend the life cycle of critical components such as switches, crossings, and brake systems.

Brake & Switch Crossing Measurement Tools

Precision Tools for Brake and Switch Crossing Measurements

We offer advanced Brake and Switch Crossing Measurement Tools designed for accurate, repeatable, and efficient data collection on rail infrastructure. These specialized systems help rail operators and infrastructure managers ensure safe and compliant railway operations by measuring dynamic and static parameters on brake forces, track geometry, and switch crossing wear. Greenwood’s innovative approach supports real-time data acquisition, reduced downtime, and predictive maintenance across a variety of rail networks.

Used by leading infrastructure operators worldwide, these tools provide essential data for condition-based maintenance planning. We combine rugged hardware with intelligent software interfaces, enabling operators to analyze trends, identify irregularities, and extend the life cycle of critical components such as switches, crossings, and brake systems.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

Accurate, Easy-to-Use Tools for Reliable Rail Testing

Smart Rail Measurement Backed by Engineering Excellence

Engineered for field reliability, our rail tools are tailored to meet the high demands of rail testing environments. Each solution is easy to install and operate, with accurate sensors and automated reporting functions that reduce human error and speed up diagnostics. Whether deployed on a trolley, onboard, or in static setups, our rail testing technology ensures precision measurements to support safe and smooth railway operations.

- Brake Force Measurement: Accurate dynamic braking force evaluation for different rolling stock types

- Switch & Crossing Wear Analysis: Monitor wear patterns to prevent derailments and optimize component lifespan

- Real-Time Data Acquisition: Wireless and onboard systems deliver immediate insights for faster decision-making

- Automated Reporting Tools: Intelligent software simplifies interpretation, trend tracking, and compliance documentation

- Modular Design: Easy integration with various vehicle platforms and measurement setups

- Built for Harsh Environments: Rugged construction ensures reliable performance in challenging rail conditions

Sectors

Sectors

Rail & Road

Solutions for infrastructure monitoring, transport safety, and structural performance assessments.

Learn MoreFAQs

FAQs

These tools measure the effectiveness of braking systems and monitor the wear and condition of switches and crossings—critical elements for rail safety and maintenance planning.

Yes, they are designed for compatibility with standard and narrow gauge railways and can be adapted for different regional requirements and rolling stock.

Measurements are captured using precise sensors and transmitted in real-time to onboard or external analysis software, where automated tools support visualization, reporting, and alerts.

These tools drastically reduce human error, improve inspection speed, and provide reliable, consistent measurements to support predictive maintenance strategies.

Infrastructure managers, railway operators, safety inspectors, and engineering firms worldwide use our tools for maintenance planning, audits, and safety assurance.