Precision Tools for Real-Time Gas Concentration Monitoring

Upgrade your process control and emissions monitoring with advanced infrared gas analyzers. Using non-contact, nondispersive infrared (NDIR) technology, these devices provide precise, continuous measurements of gas concentrations. Perfect for real-time detection of hydrocarbons, CO₂, and process gases, ensuring accuracy without the risk of sample contamination.

Reliable Instruments for Industrial and Environmental Use

Advanced Infrared Gas Solutions

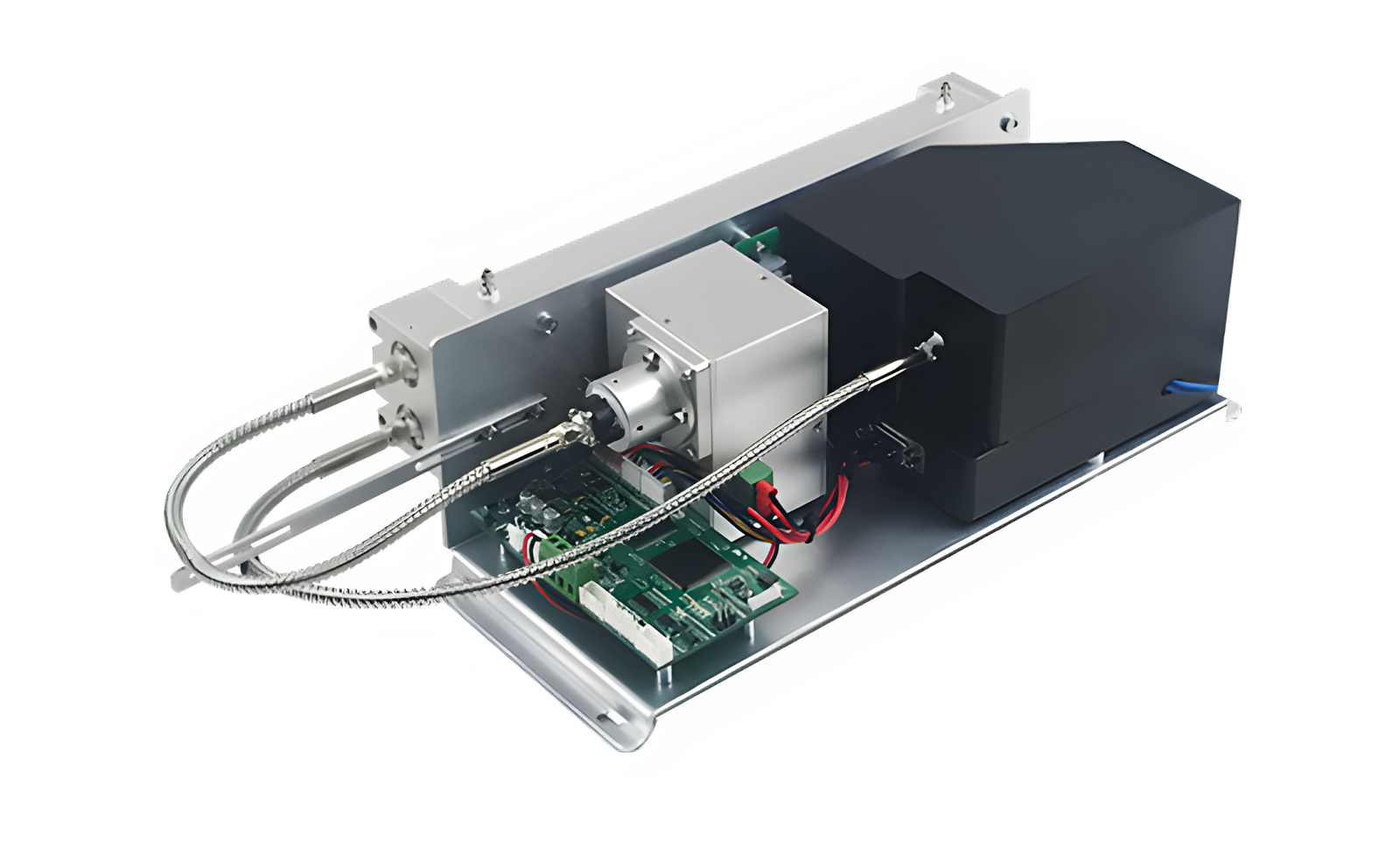

These infrared gas analyzers utilize advanced technologies like Single-Beam Single or Dual Wavelength and Spectroscopic NIR/IR to ensure stable, low-maintenance performance. Ideal for applications in process control, emissions monitoring, petrochemical production, and natural gas analysis, they are available in portable, bench, and fixed installations. With options for hazardous and safe environments, including ATEX-certified models, these analyzers deliver versatility and reliability.

Reliable Instruments for Industrial and Environmental Use

Advanced Infrared Gas Solutions

These infrared gas analyzers utilize advanced technologies like Single-Beam Single or Dual Wavelength and Spectroscopic NIR/IR to ensure stable, low-maintenance performance. Ideal for applications in process control, emissions monitoring, petrochemical production, and natural gas analysis, they are available in portable, bench, and fixed installations. With options for hazardous and safe environments, including ATEX-certified models, these analyzers deliver versatility and reliability.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

High-Precision IR Analysis for Industrial Gas Monitoring

Tailored for Critical Applications

Whether optimizing production processes, monitoring emissions, or analyzing gas compositions, these infrared analyzers provide the speed and precision required. Designed for fast response and accurate analysis, these systems offer advanced hydrocarbon speciation with minimal cross-interference and stable span calibration, ensuring reliable performance across diverse industrial applications.

- Non-Contact IR Measurement: Utilizes specific wavelength absorption for gas concentration measurement without physical interaction.

- Single-Beam Technologies:

- Compact and Fast: Low-maintenance designs deliver swift and reliable performance.

- Dual-Wavelength Stability: Offers enhanced accuracy through reference compensation.

- Spectroscopic Analysis: Advanced NIR/IR tunable-filter technology provides real-time identification of light hydrocarbons with less than 0.2% interference.

- Multi-Configuration Options: Available as portable, bench, or process-mounted analyzers to suit various operational needs.

- Robust and Low Maintenance: Incorporates non-depleting sensors, auto-calibration, and stability-focused designs to minimize upkeep requirements.

- Certified for Safety: Includes ATEX/IECEx-certified options for use in hazardous areas, ensuring compliance and safety in demanding environments.

Sectors

Sectors

Pharmacuticals

Measurement and calibration tools for research, manufacturing, and quality control…

Learn MoreFertlizer

Systems ensuring quality control, safety, and environmental monitoring in fertilizer…

Learn MoreCement & Mining Industry

Tools for vibration, safety, and structural monitoring in harsh environments.

Learn MoreAutomotive

Testing and diagnostic tools for automotive performance, safety, and durability…

Learn MoreHealth Industry

Devices and tools supporting diagnostics, research, and patient safety monitoring.

Learn MoreRail & Road

Solutions for infrastructure monitoring, transport safety, and structural performance assessments.

Learn MoreEnvironmental Monitoring

Tracks environmental parameters to ensure sustainability and regulatory compliance standards.

Learn MoreOil & Gas

Monitoring, testing, and automation systems for exploration and refinery operations.

Learn MoreConstruction Industry

Tools for structural monitoring, safety testing, and environmental condition measurement.

Learn MoreAerospace & Defence Industry

Advanced tools for testing and monitoring aerospace and defense applications.

Learn MoreManufacturing

Industrial production processes optimized using automation, testing, and monitoring technologies.

Learn MoreFAQs

FAQs

Infrared technology can measure CO₂, CO, CH₄, propane, and other infrared-absorbing gases, including light hydrocarbons like C1–C6.

Options include portable units for field use and bench or in-line analyzers for continuous monitoring in industrial processes.

Yes—many models are designed with rugged construction and certifications for use in hazardous areas, such as ATEX/IECEx.

While auto-calibration and non-depleting sensors reduce maintenance, built-in span calibration mechanisms ensure long-term accuracy.

These tools are commonly used by professionals in petrochemicals, natural gas processing, emissions monitoring, combustion control, and process quality assurance.