Vibration Measurement Tools

Maximize machine reliability with advanced vibration analysis and predictive maintenance tools.

Seamless integration, real-time diagnostics, and rugged performance for all industrial environments.

Vibration Measurement Tools

Advanced Multi-Function Analysis for Predictive Maintenance

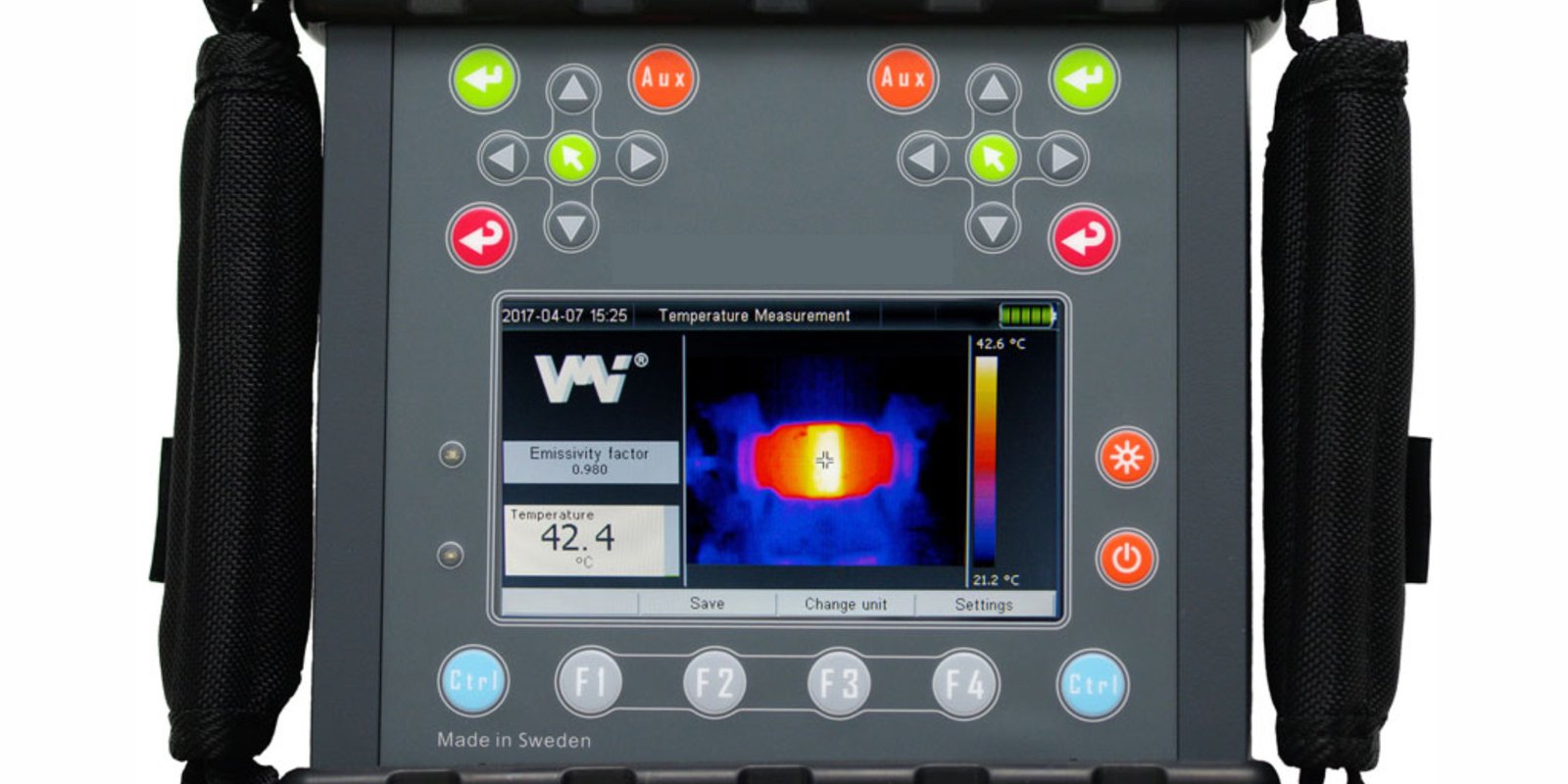

Global Tech Innovations presents vibration analyzers, built for precision condition monitoring and advanced diagnostics in industrial environments. Engineered with a high-speed floating-point DSP processor, these handheld devices deliver rapid real-time vibration analysis alongside critical machine health indicators including temperature, bearing condition, speed, and process variables. With an integrated thermal camera, these vibration analyzers detect heat anomalies and potential failures even in low-light conditions, providing a proactive edge in maintenance routines. Designed for rugged reliability, the analyzer is IP65-rated and functions in temperature extremes from -20°C to +70 °C, making it an ideal companion for field technicians and plant engineers.

Vibration Measurement Tools

Advanced Multi-Function Analysis for Predictive Maintenance

Global Tech Innovations presents vibration analyzers, built for precision condition monitoring and advanced diagnostics in industrial environments. Engineered with a high-speed floating-point DSP processor, these handheld devices deliver rapid real-time vibration analysis alongside critical machine health indicators including temperature, bearing condition, speed, and process variables. With an integrated thermal camera, these vibration analyzers detect heat anomalies and potential failures even in low-light conditions, providing a proactive edge in maintenance routines. Designed for rugged reliability, the analyzer is IP65-rated and functions in temperature extremes from -20°C to +70 °C, making it an ideal companion for field technicians and plant engineers.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

Seamless Vibration Analysis with Advanced Diagnostic Tools

Smart Integration, Intuitive Interface, and Comprehensive Compatibility

The analyzers’ user-friendly graphical interface, complete with ambidextrous keypad design and context-sensitive help, ensures smooth operation for users of all experience levels. The device supports standard vibration transducers, tachometers, and 4-20 mA process sensors, giving teams flexibility across machinery types and configurations. With built-in capabilities for both one- and two-plane balancing, and customizable setups for specific measurement points, these vibration analyzers simplify complex diagnostics and enhance the precision of predictive maintenance programs.

- Embedded thermal camera for infrared imaging and anomaly detection

- High-speed DSP processor for fast, real-time data processing

- IP65-rated design with wide operational temperature range (-20°C to +70 °C)

- Measures vibration, bearing condition, temperature, and speed

- Graphical interface with ambidextrous keypad and intuitive operation

- Compatible with standard transducers, tachometers, and 4-20 mA sensors

- Supports one- and two-plane dynamic balancing procedures

- Seamless integration with condition monitoring software.

Sectors

Sectors

Fertlizer

Systems ensuring quality control, safety, and environmental monitoring in fertilizer…

Learn MoreCement & Mining Industry

Tools for vibration, safety, and structural monitoring in harsh environments.

Learn MoreOil & Gas

Monitoring, testing, and automation systems for exploration and refinery operations.

Learn MoreManufacturing

Industrial production processes optimized using automation, testing, and monitoring technologies.

Learn MoreFAQs

FAQs

They are designed to support a broad range of rotor speeds, catering to both low-speed and high-speed rotating machinery across various applications.

Yes. They are equipped with advanced vibration analysis capabilities to identify issues such as unbalance, looseness, misalignment, and bearing faults.

Absolutely. The intuitive interface ensures ease of use for operators of all experience levels, while offering advanced functionality for professionals.

They include modern connectivity options, enabling fast charging and effortless data transfer to software platforms for detailed analysis and reporting.

These instruments are versatile and compatible with a wide range of rotating machinery, including fans, blowers, motors, spindles, and turbines.