- Home

- Application

- Ultrasonic welding through Vibration analysis

Comprehensive Solutions for Enhanced Welding Quality

Optimize welding precision and reliability with advanced ultrasonic welding systems integrated with vibration analysis. These tools provide real-time insights into the welding process, ensuring consistent quality and reducing material wastage across automotive, electronics, and packaging industries.

Ultrasonic welding through Vibration analysis

Precision Vibration Monitoring for Ultrasonic Welding

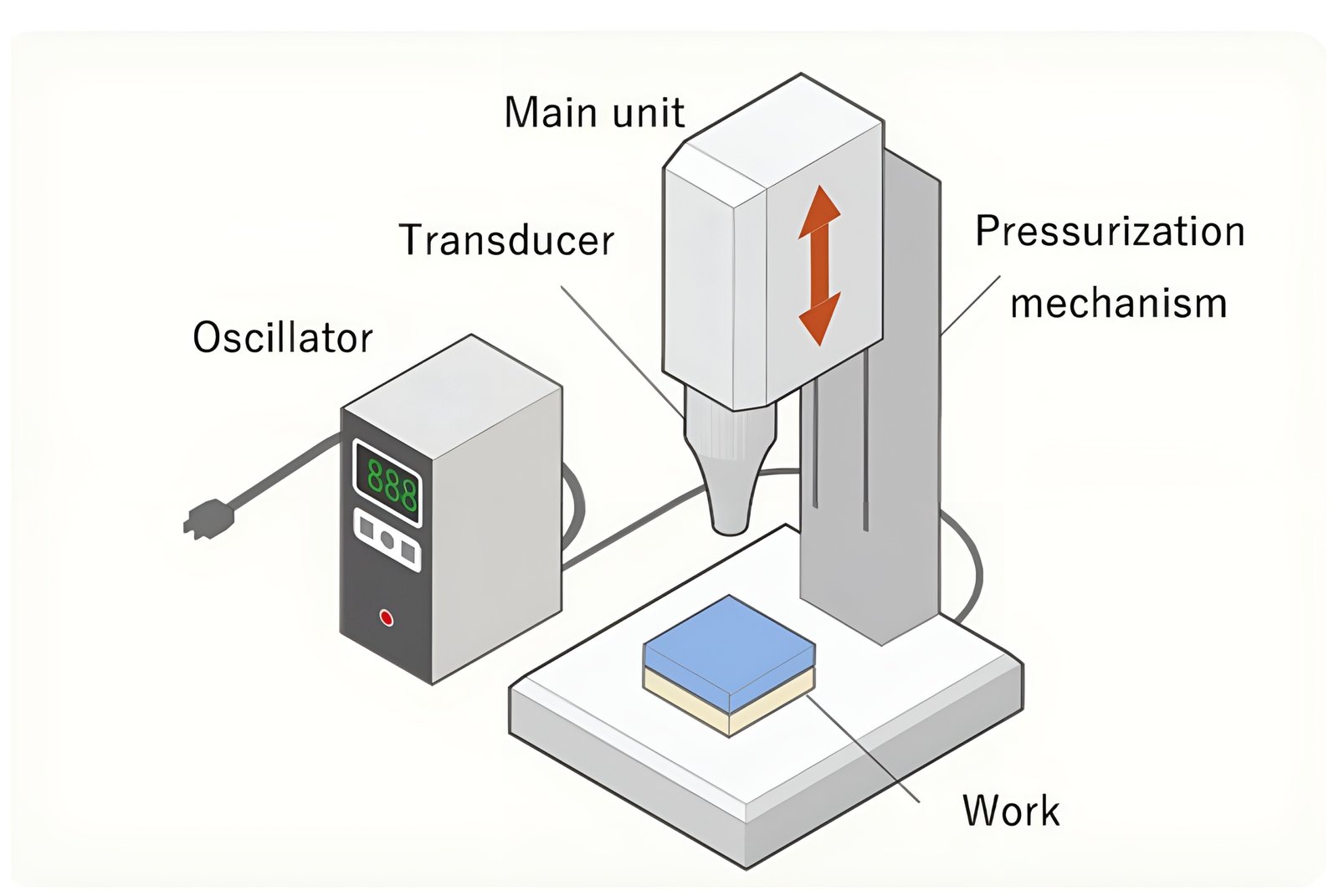

Global Tech Innovations, as the authorized distributor of Optomet, delivers next-generation ultrasonic welding systems enhanced with advanced vibration analysis. Designed to elevate welding precision and process control, these solutions provide real-time insights that ensure consistent weld quality, minimize defects, and reduce material waste across industries like automotive, electronics, packaging, and medical devices.

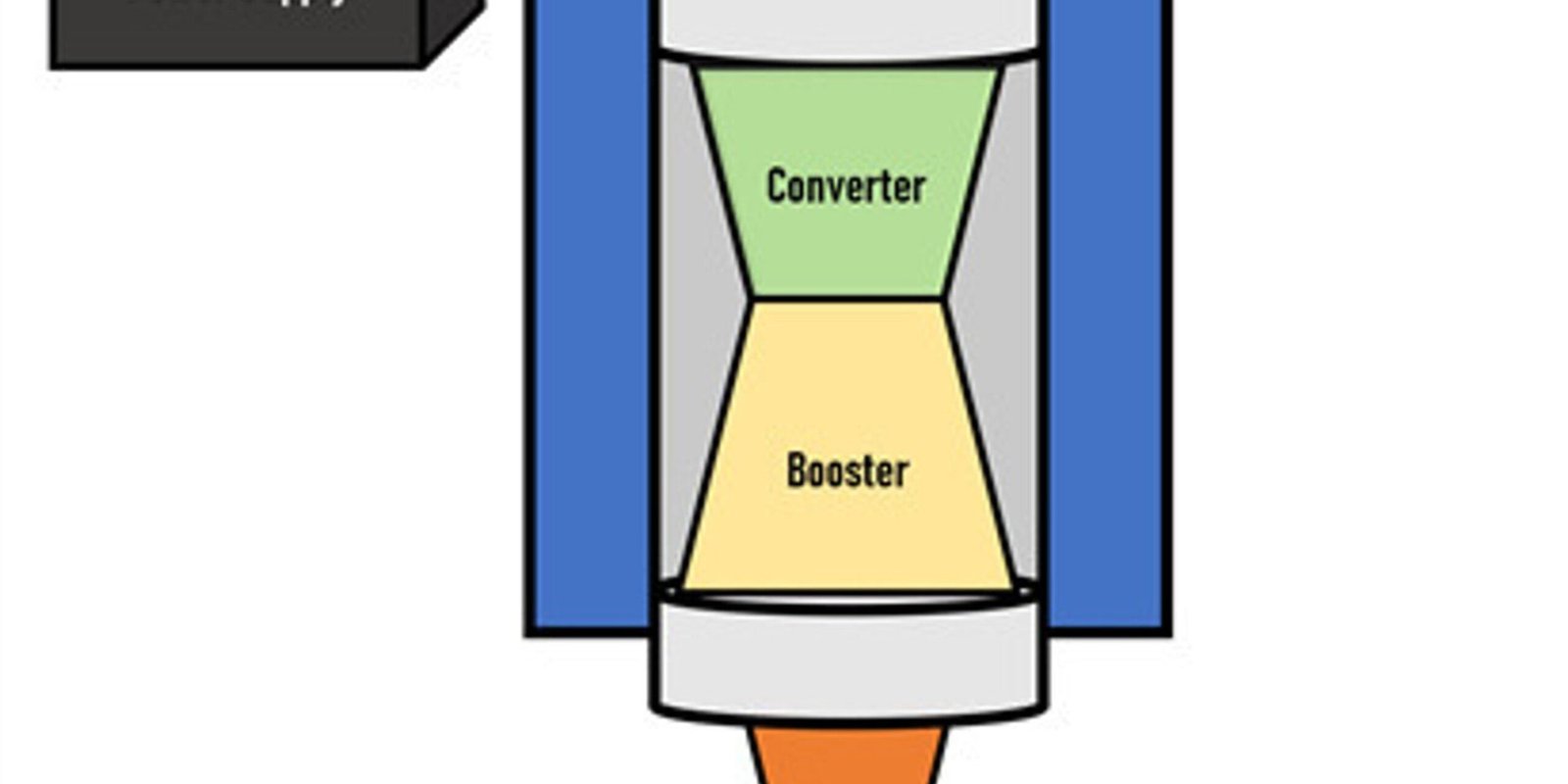

Utilizing Optomet’s cutting-edge vibration analysis technology, these systems monitor vibration frequencies and welding parameters to enhance process control, ensuring superior durability and precision in welded joints. Their innovative design supports diverse material applications, improving productivity and operational efficiency.

By delivering real-time data, Optomet’s systems help detect inconsistencies during the welding process, reducing defects, downtime, and material waste. Compatible with a wide range of materials, these solutions are ideal for automotive, electronics, and medical device manufacturing. Designed for industrial reliability, Optomet systems ensure high-quality welding results in even the most demanding production environments.

Ultrasonic welding through Vibration analysis

Precision Vibration Monitoring for Ultrasonic Welding

Global Tech Innovations, as the authorized distributor of Optomet, delivers next-generation ultrasonic welding systems enhanced with advanced vibration analysis. Designed to elevate welding precision and process control, these solutions provide real-time insights that ensure consistent weld quality, minimize defects, and reduce material waste across industries like automotive, electronics, packaging, and medical devices.

Utilizing Optomet’s cutting-edge vibration analysis technology, these systems monitor vibration frequencies and welding parameters to enhance process control, ensuring superior durability and precision in welded joints. Their innovative design supports diverse material applications, improving productivity and operational efficiency.

By delivering real-time data, Optomet’s systems help detect inconsistencies during the welding process, reducing defects, downtime, and material waste. Compatible with a wide range of materials, these solutions are ideal for automotive, electronics, and medical device manufacturing. Designed for industrial reliability, Optomet systems ensure high-quality welding results in even the most demanding production environments.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

Advanced Welding Tools | Reliable Systems for Process Optimization

Weld Smarter Today with Optomet!

Combining Optomet’s state-of-the-art vibration analysis with automated ultrasonic welding technologies, these systems deliver superior joint integrity and process control. Ideal for high-speed production lines and complex assembly processes, they ensure maximum efficiency without compromising weld quality.

- Real-Time Monitoring: Tracks vibration frequency and amplitude during welding operations.

- Enhanced Process Control: Maintains consistent weld quality across various materials.

- High Sensitivity: Detects minute variations for precise parameter adjustments.

- Durable Industrial Design: Built to withstand tough manufacturing environments.

- Multi-Industry Applications: Perfect for automotive, electronics, medical devices, and packaging sectors.

- Compliance Ready: Meets international standards for ultrasonic welding processes.

FAQs

FAQs

Industries such as automotive, electronics, packaging, and medical device manufacturing.

Yes, Optomet systems are optimized for high-speed assembly lines and continuous production environments.

Absolutely. Optomet’s vibration analysis technology provides instant feedback for in-process quality assurance.

Yes, Optomet systems support a wide range of materials including plastics, metals, and composite materials.

By minimizing defects, optimizing parameters, and reducing material wastage, Optomet’s solutions significantly enhance productivity and operational efficiency.