- Home

- Application

- Reciprocating Equipment Monitoring

Comprehensive Solutions for Machinery Health

Ensure operational reliability and prevent costly breakdowns with advanced reciprocating equipment monitoring systems. Designed for compressors, pumps, and other critical machinery, these tools provide real-time insights into performance and potential faults.

Reciprocating Equipment Monitoring

Elevating Equipment Performance with Real-Time Monitoring

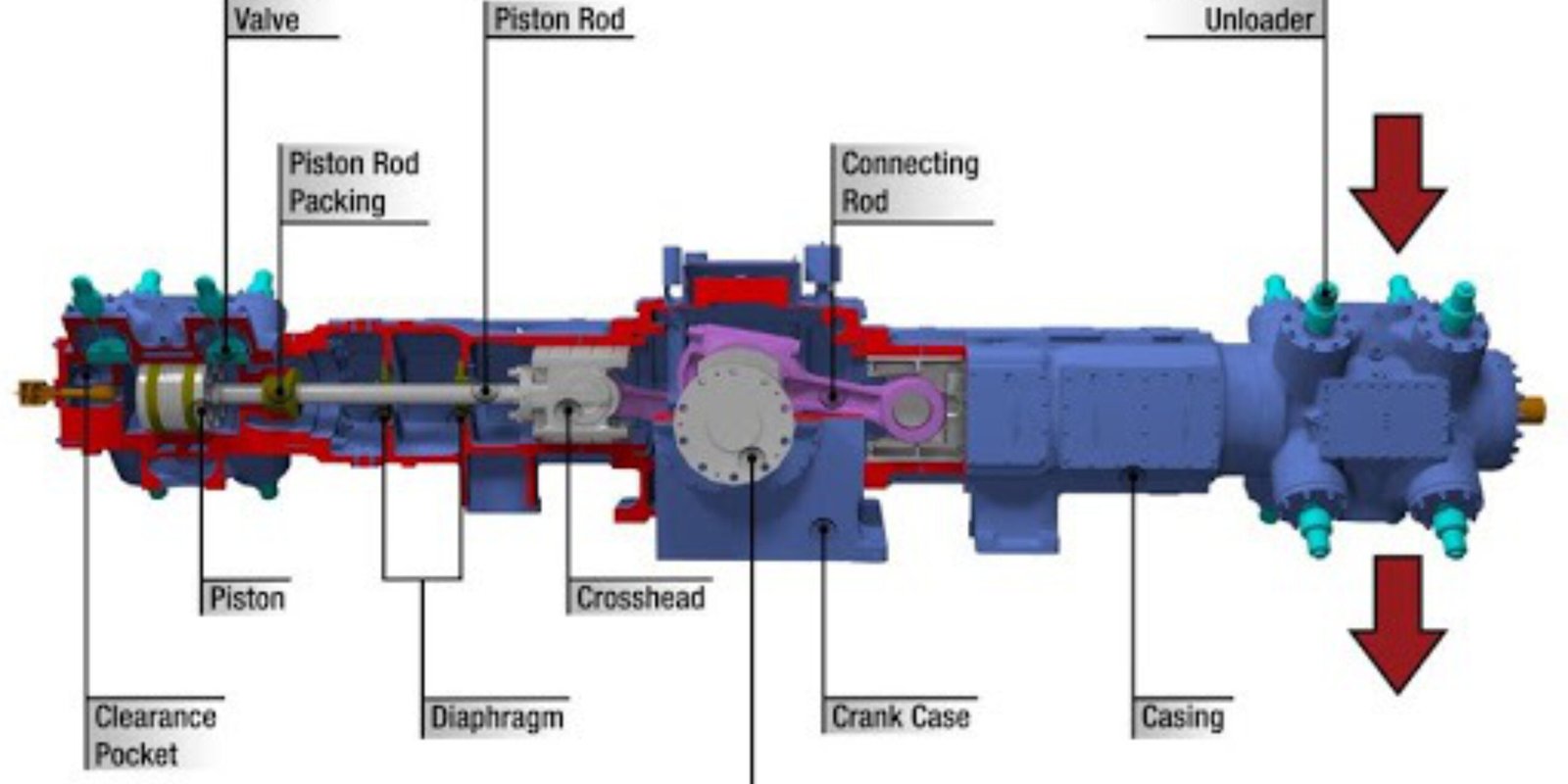

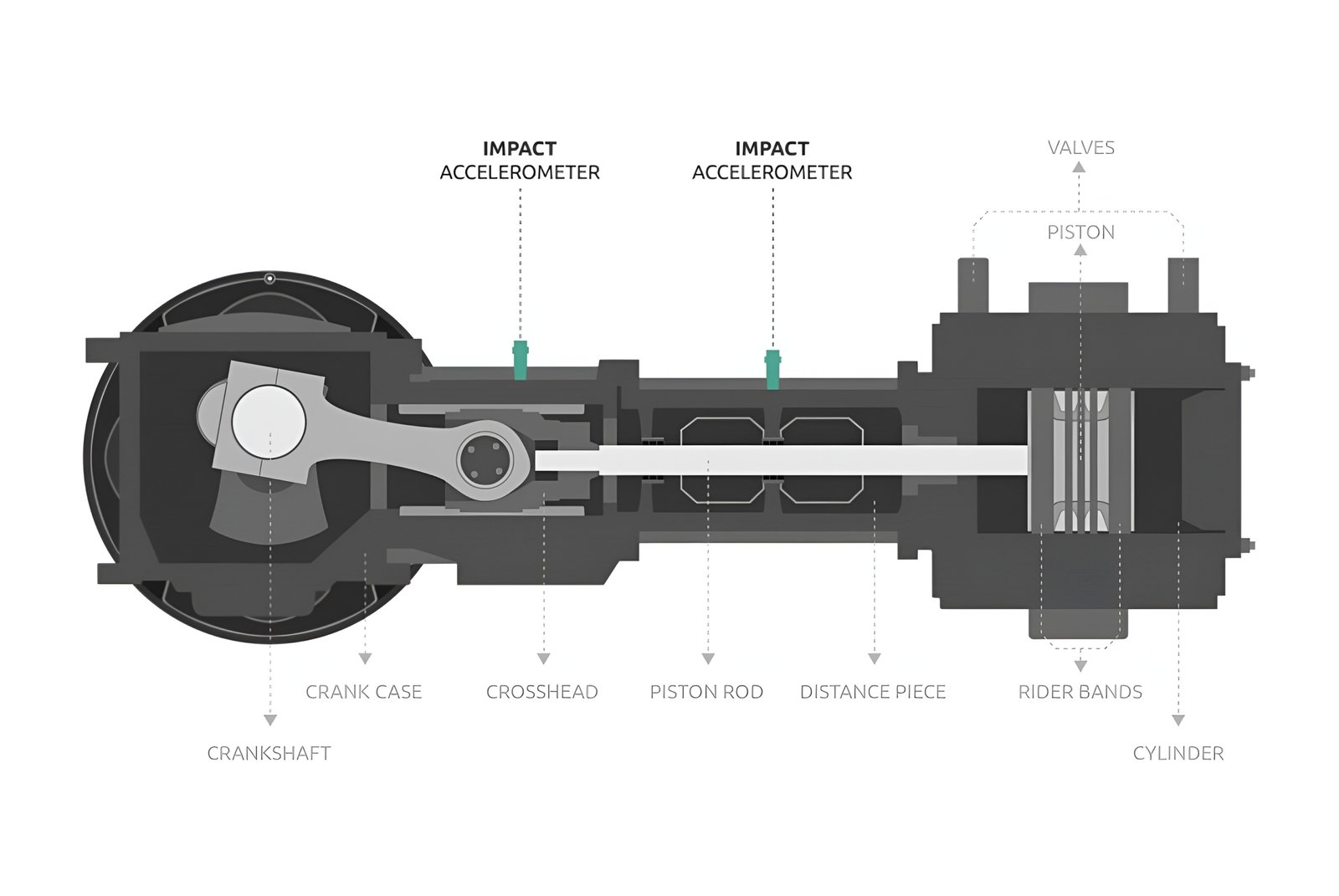

Reciprocating equipment monitoring systems play a pivotal role in maintaining operational efficiency by continuously tracking key performance metrics like vibration, temperature, and pressure. These advanced tools detect anomalies early, preventing unplanned downtime and extending the lifespan of critical machinery. Ideal for industries like oil and gas, manufacturing, and power generation, they provide actionable insights that streamline maintenance schedules and reduce costs. By leveraging predictive analytics, these systems ensure machinery operates at peak efficiency, safeguarding productivity and minimizing environmental impact.

Reciprocating Equipment Monitoring

Elevating Equipment Performance with Real-Time Monitoring

Reciprocating equipment monitoring systems play a pivotal role in maintaining operational efficiency by continuously tracking key performance metrics like vibration, temperature, and pressure. These advanced tools detect anomalies early, preventing unplanned downtime and extending the lifespan of critical machinery. Ideal for industries like oil and gas, manufacturing, and power generation, they provide actionable insights that streamline maintenance schedules and reduce costs. By leveraging predictive analytics, these systems ensure machinery operates at peak efficiency, safeguarding productivity and minimizing environmental impact.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

Reliable Tools for Predictive Maintenance

Advanced Monitoring Systems

These systems utilize high-precision sensors and analytics to detect abnormalities like vibration, pressure variations, and temperature fluctuations. With easy integration into existing setups, they enable maintenance teams to identify inefficiencies early and plan interventions proactively.

- Real-Time Diagnostics: Immediate alerts for abnormal conditions.

- Vibration Analysis: Detects issues like misalignment and wear.

- Pressure Monitoring: Ensures optimal operating conditions.

- Temperature Tracking: Identifies overheating risks.

- Predictive Insights: Data analytics for maintenance scheduling.

- Easy Integration: Compatible with diverse machinery setups.

FAQs

FAQs

Compressors, pumps, and other reciprocating machinery.

Yes, predictive insights help prevent unexpected failures.

Absolutely, with robust designs, they excel in demanding conditions.

Yes, seamless integration supports advanced process control.

By identifying issues early, they enable proactive maintenance, reducing costs.