- Home

- Application

- Laser Wheel Measurement System

Comprehensive Solutions for Railway Wheel Geometry and Safety

Ensure maximum rail safety and optimize wheel maintenance with advanced laser wheel measurement systems. These contactless, high-speed tools deliver precise geometric data for moving train and tram wheels—simplifying maintenance planning and avoiding track damage. Ideal for railway operators, maintenance yards, and infrastructure engineers.

Reliable Systems for Prevention and Precision

Advanced Wheel Measurement Tools

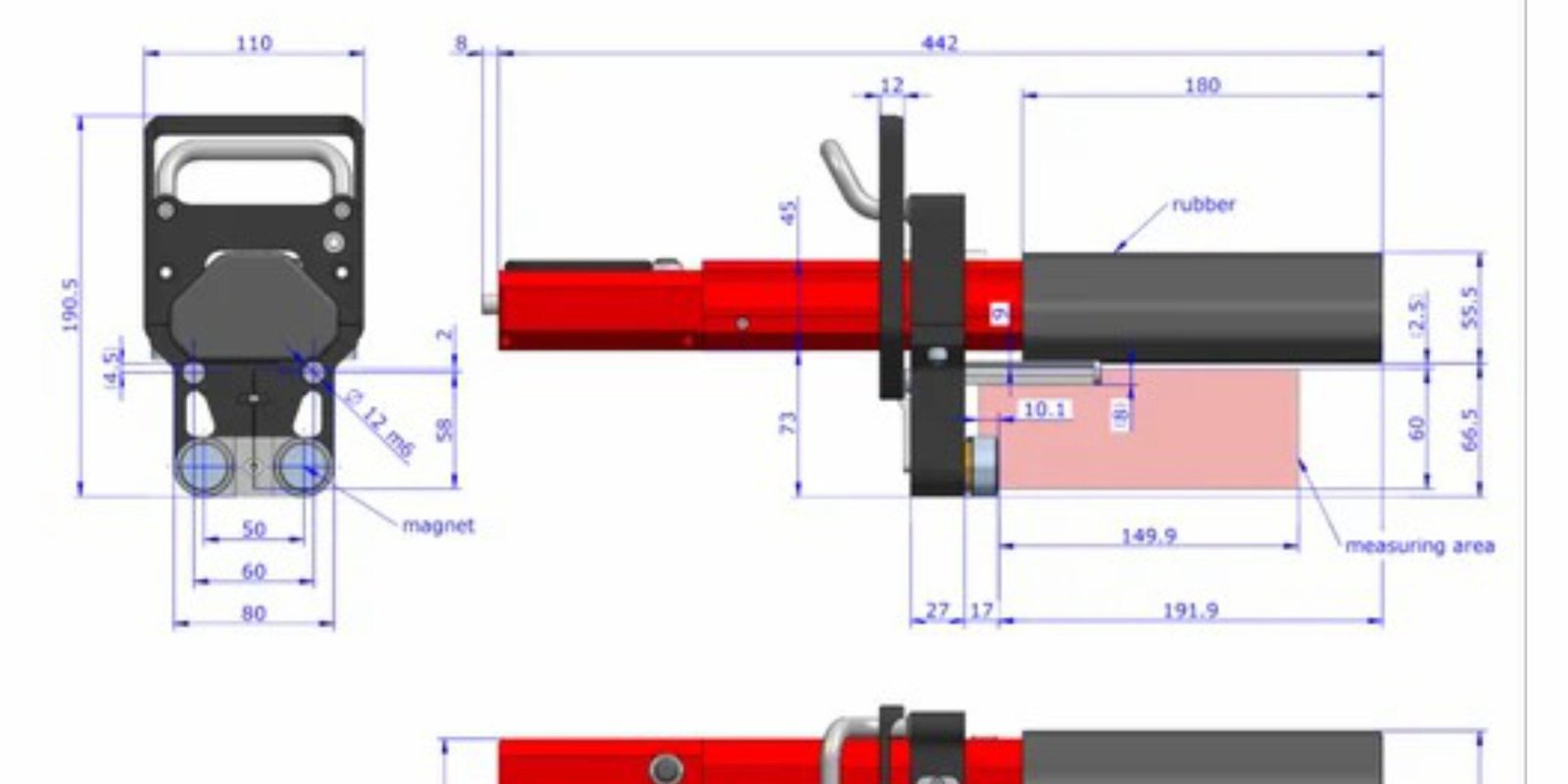

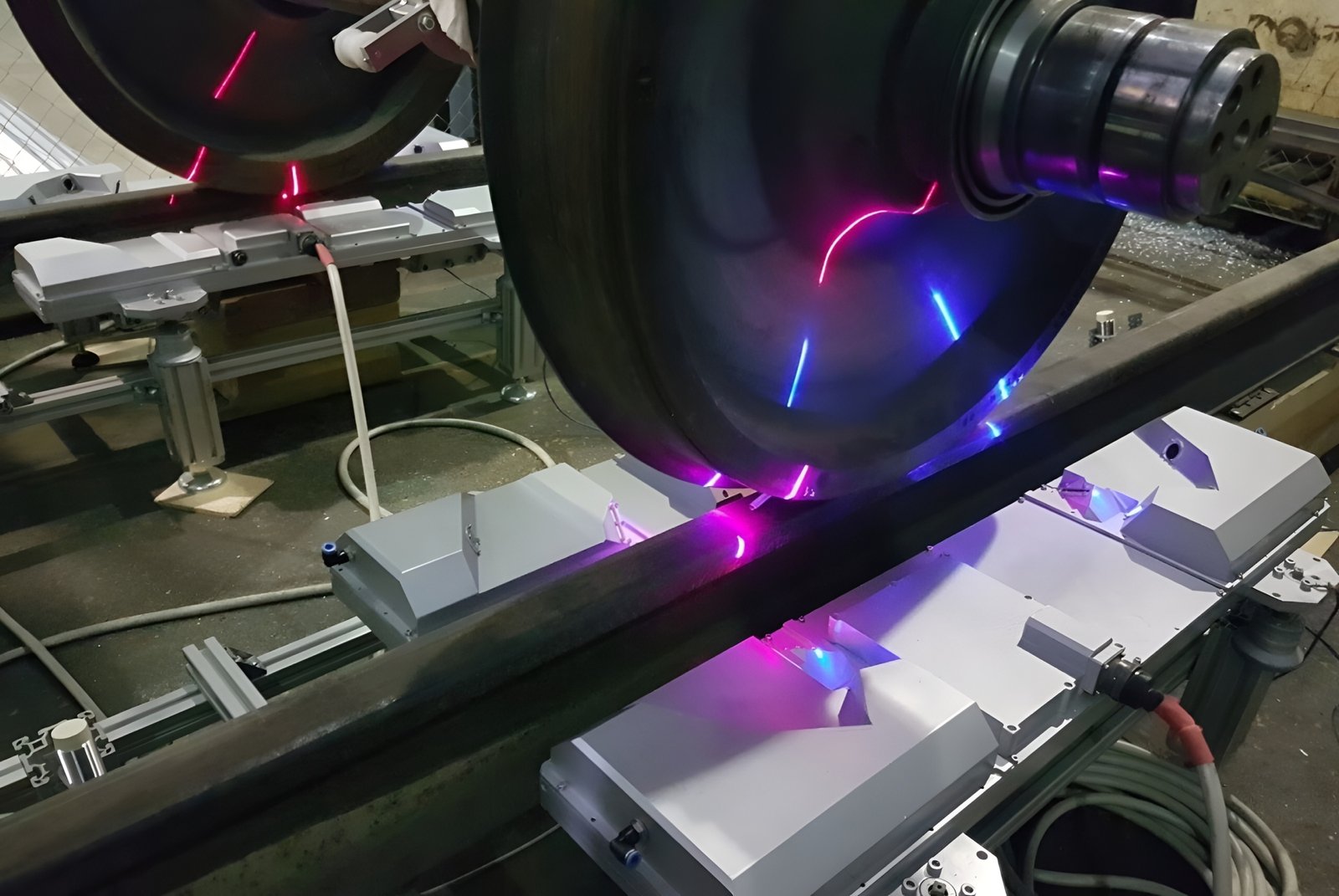

State-of-the-art systems use high-speed 2D laser scanners mounted on either side of the tracks to capture real-time wheel geometry at speeds up to 350 km/h. Measurements convert into detailed 3D point clouds and automatically calculate diameter, flange height, flange thickness, flange slope, wheel hollow wear, and back-to-back distance. With RFID-based identification and integrated cooling, cleaning, and conditioning systems, they deliver fast, reliable diagnostics to prevent infrastructure damage.

Reliable Systems for Prevention and Precision

Advanced Wheel Measurement Tools

State-of-the-art systems use high-speed 2D laser scanners mounted on either side of the tracks to capture real-time wheel geometry at speeds up to 350 km/h. Measurements convert into detailed 3D point clouds and automatically calculate diameter, flange height, flange thickness, flange slope, wheel hollow wear, and back-to-back distance. With RFID-based identification and integrated cooling, cleaning, and conditioning systems, they deliver fast, reliable diagnostics to prevent infrastructure damage.

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

Smart Laser Diagnostics for Rail Safety

Precision Monitoring for Rail Professionals

Designed for railway maintenance teams, infrastructure managers, and safety engineers, these laser systems automate wheel diagnostics without halting trains. They identify critical wear patterns and deviations quickly, streamline calibration with AI-driven software, and support both trackside and workshop environments. Their versatility and speed improve safety while minimizing downtime.

- Contactless, High-Speed Scanning: Measures wheel profiles dynamically at 15–350 km/h with 0.05 mm accuracy

- Automatic Geometric Analysis: Delivers rapid calculation of key parameters—diameter, flange metrics, hollow wear, slope, and distance between wheel pairs

- Adaptive Software Integration: Uses algorithm-driven analysis, RFID wheel and axle identification, and vision-based train detection

- Robust System Design: Enclosed sensor boxes include window heating, air cooling, cleaning, and environmental protection for year-round operation

- Scalable Installation Options: Configurable for low-speed maintenance yards (up to 15 km/h), standard rail (up to 180 km/h), or high-speed networks (up to 350 km/h)

FAQs

FAQs

Yes—it performs full wheel profiling and weighing in motion, eliminating the need for train stoppage and minimizing service disruption.

Radius, flange height/thickness/slope, back-to-back distance, hollow wear, profile angles, and axle/vehicle identification.

Versions are available for low-speed (≤15 km/h), mid-speed (≤180 km/h), and high-speed (≤350 km/h) operation.

Railway maintenance crews, operations managers, safety engineers, and infrastructure authorities seeking efficient, data-driven wheel health monitoring.

Real-time results feed dashboard platforms, alert threshold exceedances, and support predictive maintenance and regulatory reporting.