- Home

- Application

- Impact Hammer Modal Testing System

Comprehensive Solutions for Experimental Modal Analysis

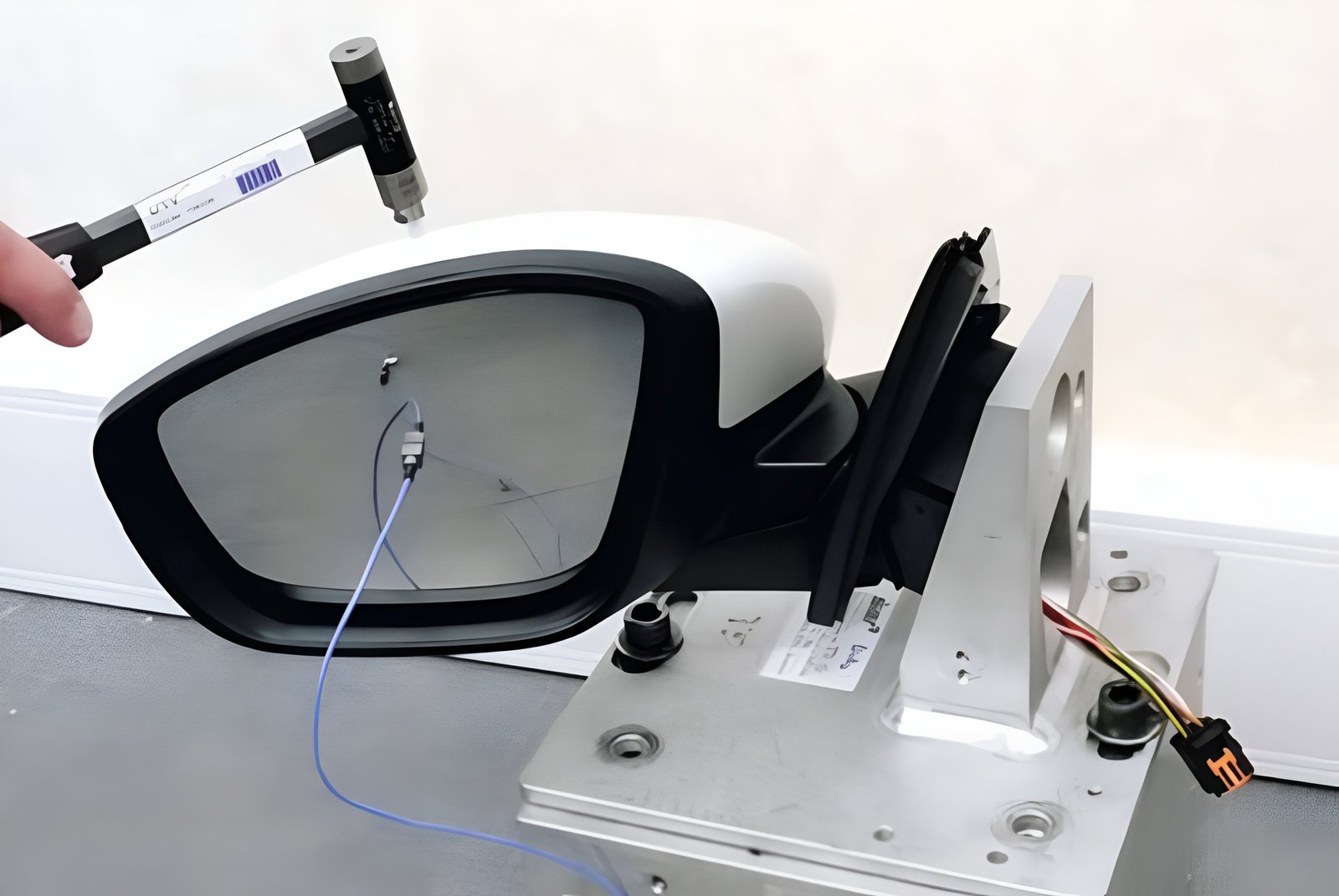

Gain deep insight into structural dynamics with cutting-edge impact hammer modal testing systems. These solutions deliver precise vibration analysis through contact and non-contact excitation and sensing—ideal for engineers, researchers, and test labs working on anything from small components to full-scale structures.

Reliable Systems for Efficient Modal Testing

Advanced Hammer Impact Tools

By using instrumented impact hammers and accelerometers, these systems excite and record structural responses, automating FRF acquisition via intuitive step-by-step software tools. Features include single-operator testing, geometry-assisted driving-point selection, adjustable triggers, manual/auto arming, and double-hit detection with acceptance/refusal options

Reliable Systems for Efficient Modal Testing

Advanced Hammer Impact Tools

By using instrumented impact hammers and accelerometers, these systems excite and record structural responses, automating FRF acquisition via intuitive step-by-step software tools. Features include single-operator testing, geometry-assisted driving-point selection, adjustable triggers, manual/auto arming, and double-hit detection with acceptance/refusal options

Advanced Tech Solutions for Your Industry Challenges

Unlock smarter, faster, and greener operations with Global Tech Innovations. From AI-powered monitoring to eco-friendly, custom-engineered solutions, we deliver cutting-edge technologies with global support and precision.

Scalable Testing for Lab and Field Applications

Precision Modal Diagnostics for Engineers

Suited for a wide range of structures—from small machinery to large industrial components—these systems support roving-hammer or roving-sensor methods (SIMO/MIMO), multi-point data capture, and advanced curve fitting analysis. Post-test visualization tools animate mode shapes and facilitate comparisons with FEA models.

- Instrumented Impact Hammers: Capture input force dynamically for accurate FRF calculation. Supports various tip stiffness for bandwidth control.

- Trigger Control & Double-Hit Detection: Adjustable trigger levels, preview windows, and auto/manual hit rejection prevent data distortion.

- Driving Point Selection: Pre-test FRF sweeps identify the optimal excitation location for clear mode detection.

- Roving Methods: Supports SIMO (roving hammer, fixed sensors) or roving-sensor approaches; tri-axial options reduce test time.

- Multi-Channel DAQ Integration: Compatible with handheld or high-channel systems—scale from small benches to complex structures.

- Analysis & Visualization Suite: Includes automated modal parameter extraction (natural frequencies, damping, mode shapes) with interactive geometry model animation.

FAQs

FAQs

It involves using an instrumented hammer to excite structures with a controlled impulse, measuring the force and response to generate FRFs for modal parameter extraction.

Trigger settings capture full waveforms including pre-triggers; automatic or manual hit rejection removes double impacts for clean data sets.

Roving hammer (SIMO) or roving sensor setups are supported, with tri-axial sensor options for efficient multi-directional data capture.

Powerful software automates FRF processing, curve-fitting modal parameters, and animates mode shapes for intuitive insight and correlation with FEA models.

Engineers, researchers, and test labs involved in product design, structural validation, failure analysis, and compliance testing benefit from modal hammer testing solutions.