- Home

- Sector

- Oil & Gas

Oil & Gas

Precision Monitoring Solutions for Oil & Gas

Explore advanced sensing and condition monitoring tools engineered for the oil and gas sector. Global Tech Innovations curates high-integrity instrumentation built to operate in hazardous environments and support predictive strategies for safer, smarter, and more efficient field operations.

Unlock Your Potential with Expert-Led Learning Paths Across Various Fields

Oil & Gas

- Home

- Sector

- Oil & Gas

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Instrumentation in Oil & Gas Operations

Engineered for Harsh Sites

In the oil and gas sector, the margin between performance and failure is razor-thin. Operations depend on precise monitoring, rapid response, and long-term reliability under extreme pressures, temperatures, and environmental hazards. Global Tech Innovations offers insight into instrumentation technologies designed to improve operational safety and efficiency across upstream, midstream, and downstream processes.

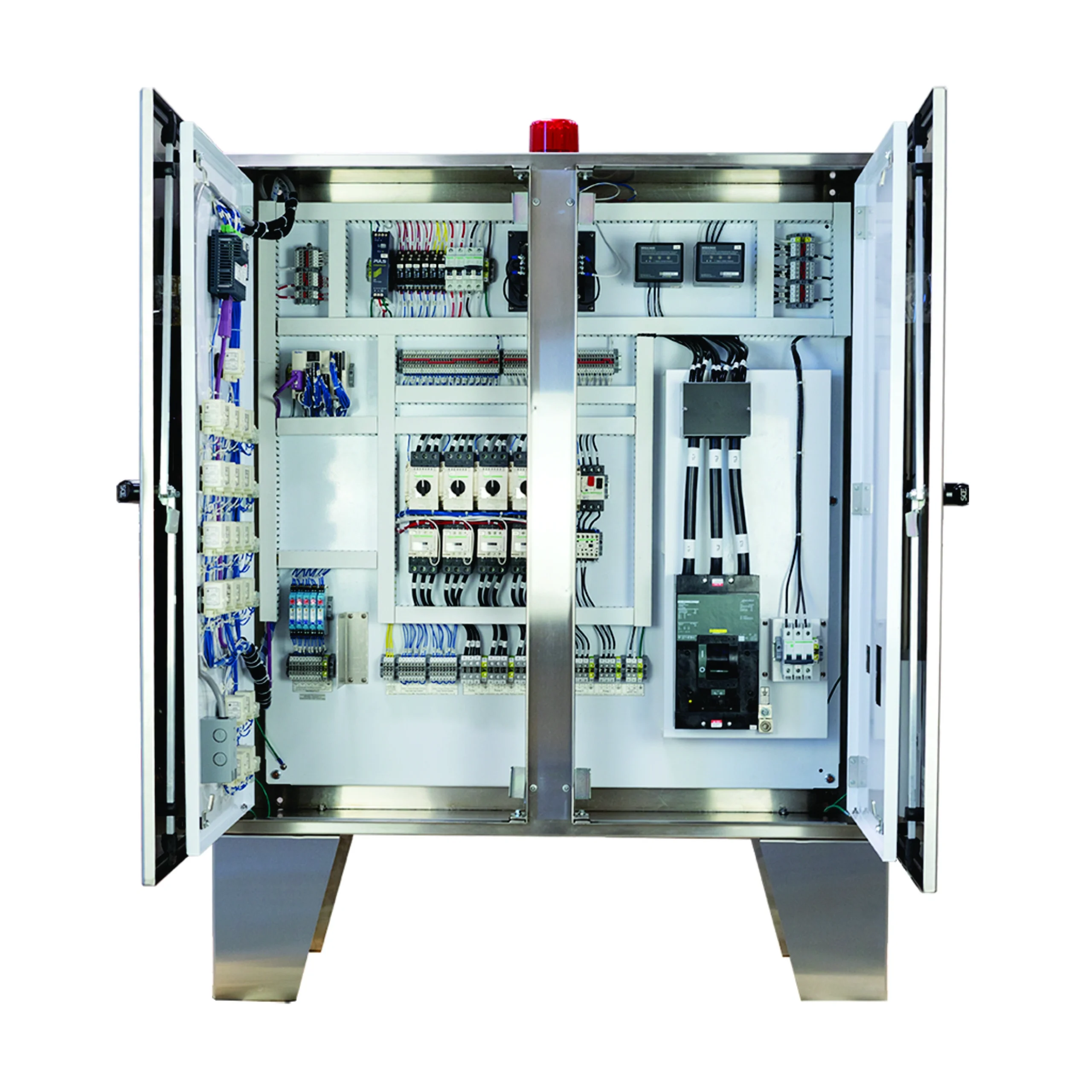

From drilling platforms to refineries, advanced vibration sensors and pressure monitoring solutions support predictive maintenance and equipment diagnostics. These tools help detect issues like imbalance, misalignment, or seal failure before they escalate. With digital integration into SCADA, DCS, and PLC systems, these technologies play a vital role in optimizing asset health and minimizing unplanned downtime—all while maintaining compliance in hazardous and regulated environments.

Instrumentation in Oil & Gas Operations

Engineered for Harsh Sites

In the oil and gas sector, the margin between performance and failure is razor-thin. Operations depend on precise monitoring, rapid response, and long-term reliability under extreme pressures, temperatures, and environmental hazards. Global Tech Innovations offers insight into instrumentation technologies designed to improve operational safety and efficiency across upstream, midstream, and downstream processes.

From drilling platforms to refineries, advanced vibration sensors and pressure monitoring solutions support predictive maintenance and equipment diagnostics. These tools help detect issues like imbalance, misalignment, or seal failure before they escalate. With digital integration into SCADA, DCS, and PLC systems, these technologies play a vital role in optimizing asset health and minimizing unplanned downtime—all while maintaining compliance in hazardous and regulated environments.

Applications

Applications

Wireless Machine Condition Monitoring System

Tracks machine health remotely using sensors for predictive maintenance insights.

Impact Hammer Modal Testing System

Measures structural response to impact for modal analysis studies.

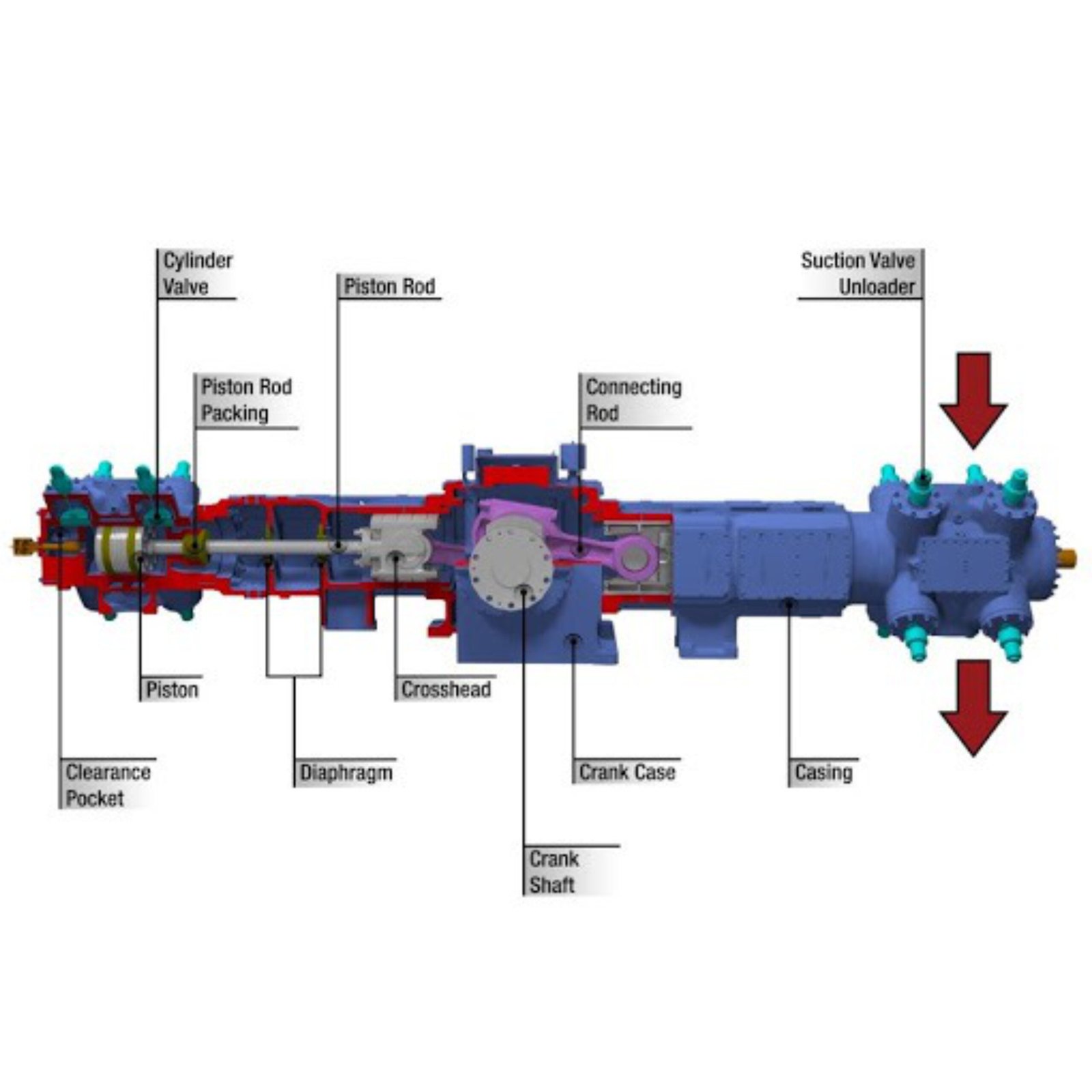

Reciprocating Equipment Monitoring

Tracks piston equipment health to avoid unplanned maintenance or failures.

Product Line

Explore Cutting-Edge Solutions for Precision and Performance

Advanced Sensing & Safety Monitoring

Built for Tough Zones

The operational challenges in oil and gas environments demand instrumentation built to withstand extremes. Global Tech Innovations presents monitoring tools that provide high-fidelity data, structural insights, and safety compliance in combustible or corrosive conditions.

- Explosion-rated vibration sensors compliant with ATEX and CSA standards

- Charge-mode pressure sensors suited for turbines and pipelines

- 4–20 mA transmitters for seamless SCADA system integration

- Laser vibrometry for non-contact diagnostics in rotating assets

- Noise dosimeters and human vibration meters for workforce exposure monitoring

- Real-time edge processing and Modbus-compatible digital outputs

- Intrinsically safe enclosures and signal conditioning electronics

- Rugged, weatherproof HSE monitoring tools for acoustic and vibration safety

Products

Products

Test & Measurement Sensors

Capture accurate data for testing mechanical, electrical, and physical parameters.

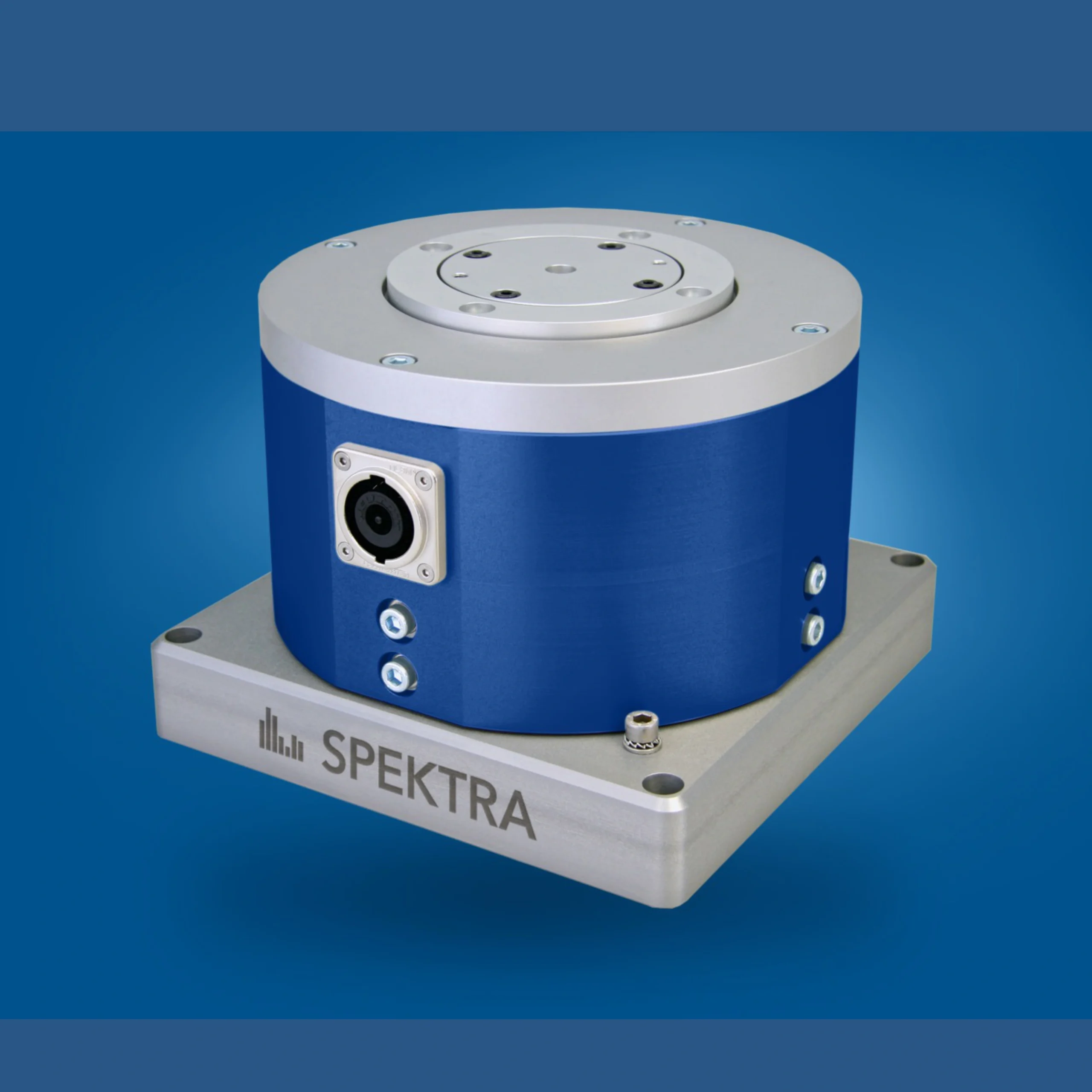

Digital Vibration Sensor

Measures vibration digitally for precision monitoring and predictive maintenance.

Motor Testing Tools

Evaluate motor condition and performance through electrical and mechanical diagnostics.

Digital Multimeters

Measure voltage, current, and resistance for electronic and electrical troubleshooting.

Power Quality Analyzers

Monitor voltage stability, harmonics, and power anomalies in electrical systems.

Vibration Sensor Calibrators

Calibrate vibration sensors to maintain accurate and reliable measurements.

Microphone & SLM Calibrators

Verify sound measurement accuracy for microphones and sound level meters.

Pressure Sensors Calibrators

Ensure accurate pressure sensor output through precise calibration routines.

Noise Monitoring Tools

Continuously monitors environmental or industrial noise levels for compliance.