- Home

- Sector

- Power Plants

Power Plants

Industrial Instrumentation for Power Plants

Explore robust sensing, monitoring, and automation solutions built to support modern power generation environments. Global Tech Innovations highlights tools that improve operational visibility, prevent faults, and help ensure high-efficiency performance across thermal, hydro, and renewable energy facilities.

Unlock Your Potential with Expert-Led Learning Paths Across Various Fields

Power Plants

- Home

- Sector

- Power Plants

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Mining

- Grizly feeder

- Jaw Crusher

- Virbation Screen

- Ball Mill

- Stacker Reclaimer

- Cyclone Separator

- Conveyor

Measurement & Monitoring for Power Plants

Precision for Plant Efficiency

Power plants operate under rigorous conditions where thermal, mechanical, and environmental factors must be continuously monitored to maintain operational efficiency and prevent failure. Global Tech Innovations offers advisory insight into the tools and technologies that help optimize performance, from turbine vibration tracking to high-temperature pressure sensing.

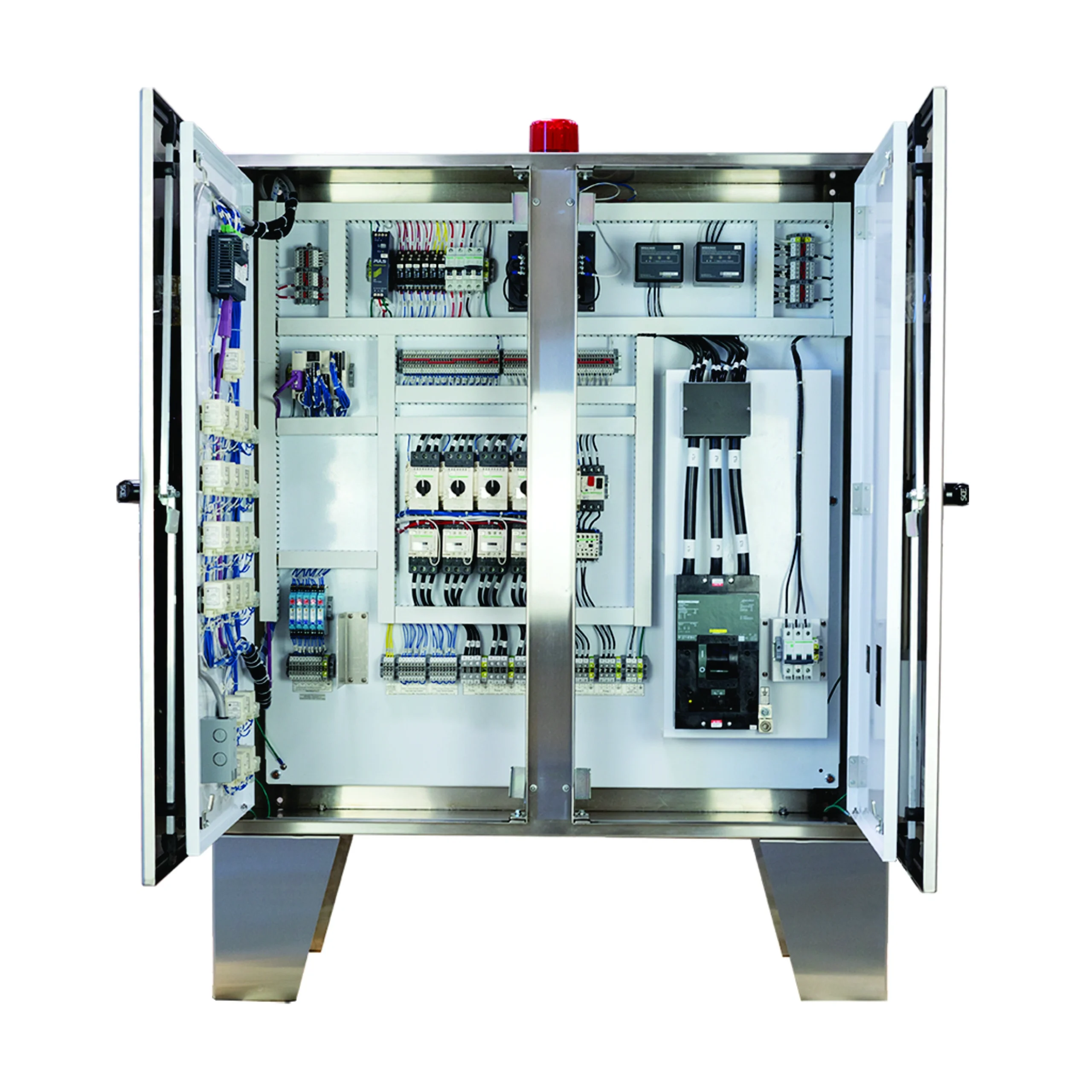

With assets ranging from generators to boilers and combustion chambers, accurate diagnostics are crucial to help ensure reliability and regulatory compliance. Vibration sensors, pressure transducers, and safety monitoring devices support proactive maintenance by identifying early signs of imbalance, misalignment, or stress-induced fatigue. Integrated automation and control systems improve data transparency, while calibrated measurement tools support critical checks across turbine shafts, pump systems, and electrical circuits. By adopting these technologies, power plants not only extend equipment life but also help ensure safe and uninterrupted energy generation under demanding conditions.

Measurement & Monitoring for Power Plants

Precision for Plant Efficiency

Power plants operate under rigorous conditions where thermal, mechanical, and environmental factors must be continuously monitored to maintain operational efficiency and prevent failure. Global Tech Innovations offers advisory insight into the tools and technologies that help optimize performance, from turbine vibration tracking to high-temperature pressure sensing.

With assets ranging from generators to boilers and combustion chambers, accurate diagnostics are crucial to help ensure reliability and regulatory compliance. Vibration sensors, pressure transducers, and safety monitoring devices support proactive maintenance by identifying early signs of imbalance, misalignment, or stress-induced fatigue. Integrated automation and control systems improve data transparency, while calibrated measurement tools support critical checks across turbine shafts, pump systems, and electrical circuits. By adopting these technologies, power plants not only extend equipment life but also help ensure safe and uninterrupted energy generation under demanding conditions.

Applications

Applications

Wireless Machine Condition Monitoring System

Tracks machine health remotely using sensors for predictive maintenance insights.

Agriculture Monitoring System

Monitors crop conditions using environmental and soil sensors in real-time.

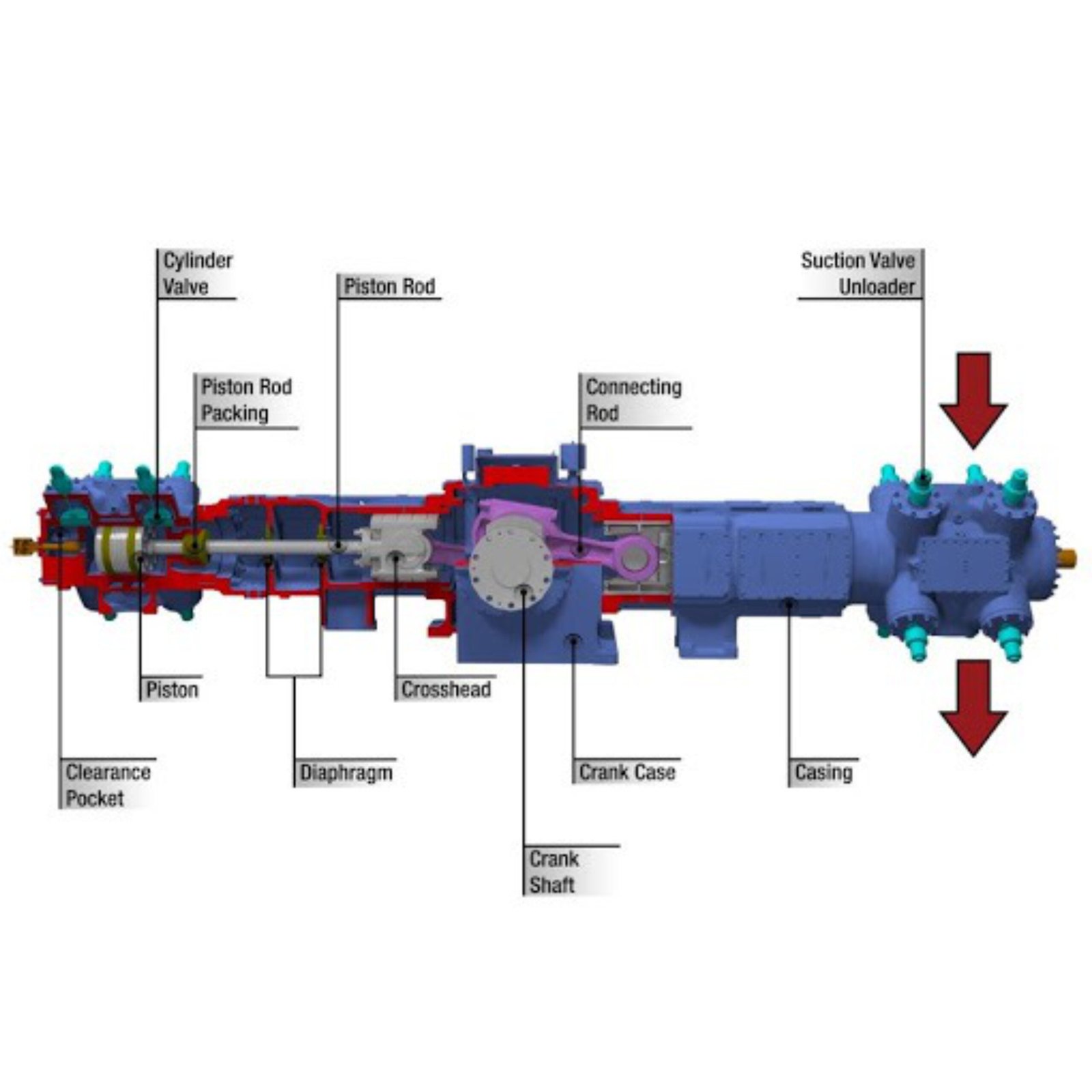

Reciprocating Equipment Monitoring

Tracks piston equipment health to avoid unplanned maintenance or failures.

Product Line

Explore Cutting-Edge Solutions for Precision and Performance

Condition Monitoring & Diagnostic Tools

Optimizing Plant Uptime

Global Tech Innovations curates intelligent instrumentation that improves the reliability and safety of power generation systems. These tools support comprehensive condition monitoring and diagnostic routines essential for thermal, hydro, and combined-cycle power plants.

- Digital Vibration Sensors: Real-time fault detection with protocol support for SCADA/PLC integration

- 4–20 mA Vibration Transmitters: Continuous monitoring for rotating and reciprocating assets

- Industrial Pressure Sensors: Designed for combustion stability and pipeline monitoring

- Laser Vibrometry Systems: Non-contact testing for turbine blades and large-scale equipment

- Human Vibration & Noise Meters: Safeguard operator health in high-decibel zones

- Enclosure Systems: Robust, industrial-grade housing for vibration and pressure diagnostics

- Calibration Tools: Ensure precise system performance and traceability

- Automation Interfaces: Seamless integration into existing power control architecture

Products

Products

Test & Measurement Sensors

Capture accurate data for testing mechanical, electrical, and physical parameters.

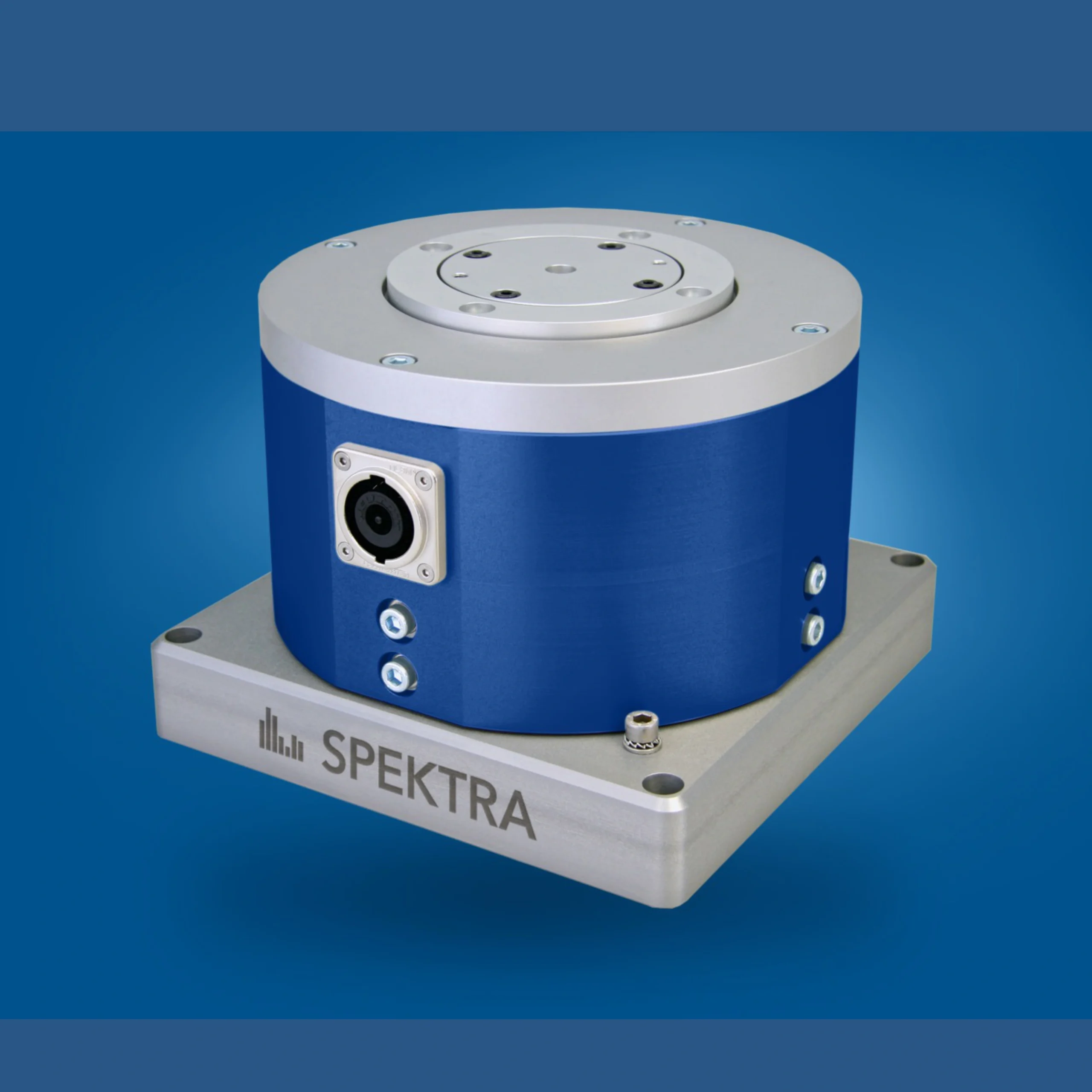

Digital Vibration Sensor

Measures vibration digitally for precision monitoring and predictive maintenance.

Motor Testing Tools

Evaluate motor condition and performance through electrical and mechanical diagnostics.

Digital Multimeters

Measure voltage, current, and resistance for electronic and electrical troubleshooting.

Power Quality Analyzers

Monitor voltage stability, harmonics, and power anomalies in electrical systems.

Vibration Sensor Calibrators

Calibrate vibration sensors to maintain accurate and reliable measurements.

Microphone & SLM Calibrators

Verify sound measurement accuracy for microphones and sound level meters.

Pressure Sensors Calibrators

Ensure accurate pressure sensor output through precise calibration routines.

Noise Monitoring Tools

Continuously monitors environmental or industrial noise levels for compliance.